Welded continuous slot wedge wire screen with plain end

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Welded continuous slot wedge wire screen with plain end

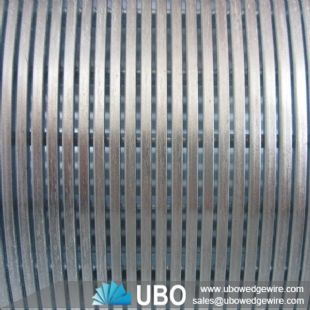

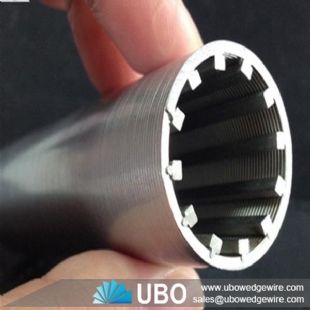

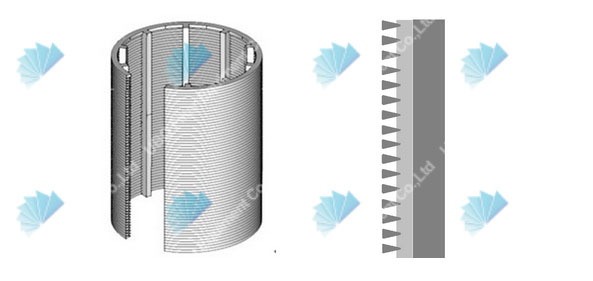

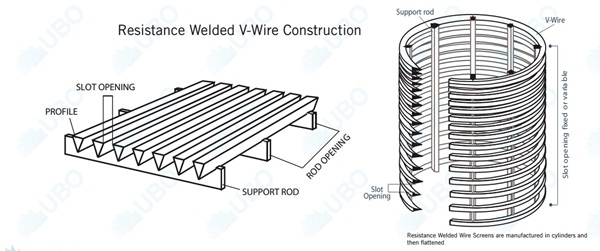

Welded continuous slot wedge wire screen is composed of ribs(vertical ribs or support ribs) and V-shaped wire, adopting the advanced full contour welding fabrication process. Each intersection is connected by fusion welding, that it has strong structure, good mechanical performance. The continuous uniform stability of screen slots is controlled by the computer system.

The continuous slot formed by the V-shaped wires ensures a two-point contact between the particles and the slot, which minimizes clogging, and maintain smooth flow.

Continuous slots ensure larege aperture ratio, larger flow area, and minimize underwater velocity of permeability, keeping sands away from the pipes even in higher water pressure. Slot size can vary according to difference service.

Advantage of Welded continuous slot wedge wire screen with plain end

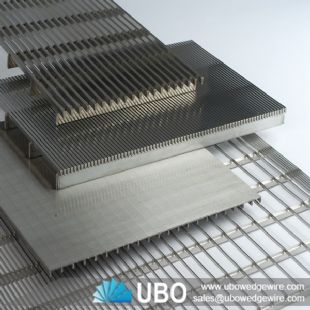

*The continuous V-shaped profile minimizes clogging and maintains smooth flow, making it more efficient.

*V-shaped filtration slots help to improve self back flushing capacity.

*High density uniform screen slots ensure larger aperture ratio and no clogging, which greatly improve working efficiency and prolong water well service life.

*The fusion welding between wedge wire and all support wires, makes it strong enough to bear larger crush pressure.

Uses of Welded continuous slot wedge wire screen with plain end

The strainer is a kind of filtered water tubing with the perforation .it can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filters.

Specifications of Welded continuous slot wedge wire screen with plain end:

Slot(mm):up to 25, 0.025 for minimum, available to fabricate according to customer’s requirement or site condition.

Opening ratio: opening area can be up to 60%

Material: stainless steel(304,316L,321 etc.). Special material or alloy material is available for customers’ requirement of special service.

Length (mm): Max. available length is 6000.

Nominal diameter(mm): up to 1200, 25 for minimum.

Connection: groove butt welding connection or threaded connection.

Packaging and Transportation of Welded continuous slot wedge wire screen with plain end: