V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel 304,304L,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen cylinder |

| Application: | water-treatment,beer brewing,water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant,refining & petrochemical |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

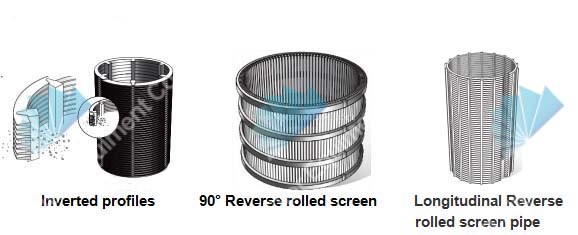

Details of V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration

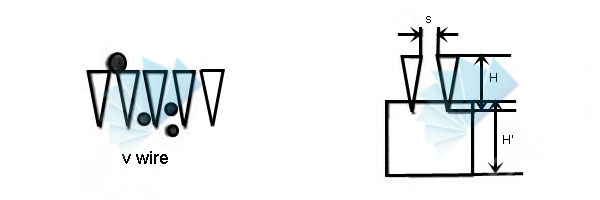

Wedge Wire type V-Shaped Stainless Steel Wedge Wire Drum Screen Cylinder is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities while at the same time keeps the majority of sand and gravel out of the well.

Advantages of V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration

V-Shaped Slots: Openings shaped like a "v" that open toward the inside of the well tend to allow the particles that are just barely smaller than the width of the slot pass. In other shapes of openings, these particles would get caught in the screen and clog it.

Continuous Slots: The special design gives continuous slot opening across the periphery and length of screen.

Very Large Open Area: This design gives continuous slot and hence the% open area for water to enter is more than 2 times that of conventional slotted pipes of any size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably.

Better Sand Filtration: Due to specialize manufacturing process, wide range of slot opening is available down to 0.15mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

Energy Saving: Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.

Application of V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration

Be suitable for all kinds pressure screen in pulp making system and paper making system.

The stainless steel wedge wire screen cylinder is perforation/hole or slot/wedge wire structure designed to achieve high efficiency screening of recycled, mechanical, and paper pulp fiber. The patent-pending design features a robust mechanical assembly and a high-precision wire positioning system to minimize slot width deviation.

Specifications of V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration:

|

|

|||||||

|

Material |

SS304, SS304L, SS316, SS316L, SS321, Duplex, Hastelloy, etc |

||||||

|

OD Range |

Min 68mm, the biggest according to clients’ request |

||||||

|

ID Range |

MIN 60mm, the biggest according to clients’ request |

||||||

|

Length Range |

Up to 6000 mm |

||||||

|

Slot Range |

20 micron to 3000 micron (Tolerance:+-5 micron) |

||||||

|

Wedge Wire |

0.5x1.5 |

0.75x1.5 |

1x2 |

1.5*2 |

2x3 |

2*4 |

3*5 |

|

Support Rod |

1.5x2.5

2x3 |

1.5x2.5

2x3 |

1.5x2.5

2x3 |

1.8*2.5

2x3 |

2x3

2x4

3x5

3x6

3x10

4x7 |

2x4

3x5

3x6

3x10

4x7

5x6 |

3x5

3x6

3x10

4x7

5x6

5x8 |

|

End Finishing |

Thread fitting, Flange, Closed Plated, Resistance welded closed plate, Metal Ring, etc |

||||||

|

Note |

Customized According To Requirement |

||||||

Packaging and Transportation of V Shaped Wedge Wire Drum Screen Cylinder for Liquid Filtration: