Profile Wire tube Screens for Process Industries

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire pipe |

| Application: | solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Profile Wire tube Screens for Process Industries

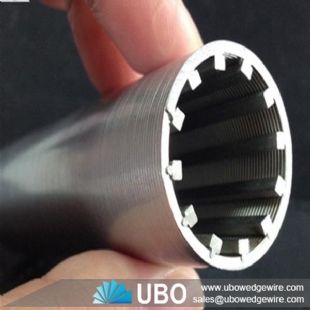

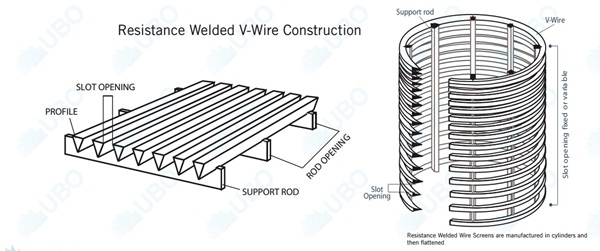

Wedge Wire Profile Wire Wrapped Pipe Screen For Water Treatment is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding,easily fit for various of water screening in lakes, rivers and other natural bodies of water in water and wastewater treatment.

Application for Profile Wire tube Screens for Process Industries:

Wedge wire filters are used in chemical industry, sieving of petroleum, pharmaceutics, metallurgy and coal, food and beverage, also can be used in filtration of water treatment. Wedge wire filters are the most popular mining screen due to its strength.

Characteristics for Profile Wire tube Screens for Process Industries:

1.They consist of V-shape or wedge shape profile wire and the longitudinal support rods.

2.The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can filter sand better.

3.Each intersecting point of these wires is fusion welded, so it has sturdy construction and good mechanical property.

Features for Profile Wire tube Screens for Process Industries:

1).adoption of the wedged wires made a V profile slot. This design ensures the fluent of water filteration and more effective.

2).wedged wires are spirally wound around a cage of longitudinal support rods in succession which formed high-density uniformed slots and avoid clogging. So that the high production efficiency and long life service of the well are gaurenteed.

3).arrangement of the longitudinal support rods and the successive slots provide higher compressive property

Advantages for Profile Wire tube Screens for Process Industries:

•Optimum quality (pre-filtered water)

•Low running cost

•Low maintenance

•Avoids biological activity (algae, plankton, etc)

•Easily cleanable

•Environmentaly friendly, avoiding negative impact

•Constant feed (not decreasing over time)

•Flexibility to adjust the water flow

Specifications of Profile Wire tube Screens for Process Industries:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Width |

from 25mm to 1200mm. |

|

Radian |

15 |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of Profile Wire tube Screens for Process Industries: