wedge wire flat panel applications

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

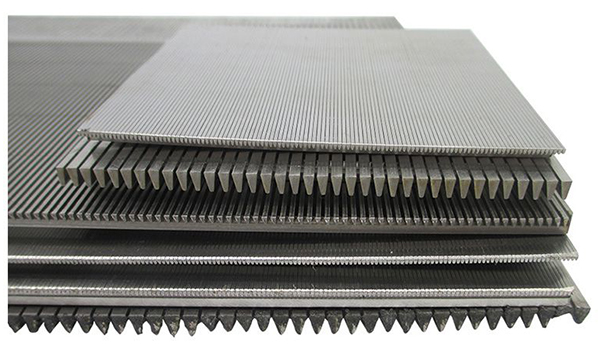

In the demanding world of industrial processing, efficiency, durability, and precision are paramount. Wedge wire flat panels, also known as V-wire screens, profile wire screens, or slotted screens, are engineered marvels that deliver exceptional performance across a multitude of applications. At Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as “YUBO”), we specialize in custom-manufacturing high-quality wedge wire flat panels designed to meet the unique challenges of various sectors, with a particular expertise in serving the robust needs of the mining industry.

If you're searching for "wedge wire flat panel," "wedge wire flat panel application," or solutions for demanding screening and separation tasks, you've come to the right place. This article explores the versatility and critical benefits of these essential components.

What Makes Wedge Wire Flat Panels the Superior Choice?

Before diving into specific wedge wire flat panel applications, let's understand their core advantages:

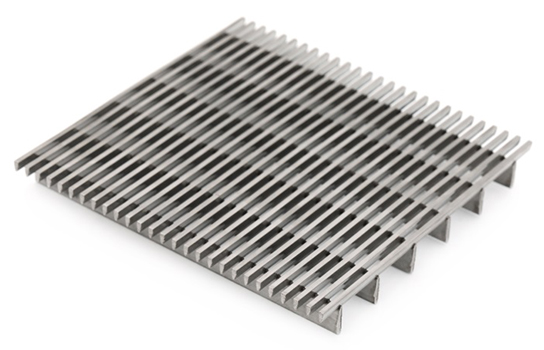

1.Non-Clogging Design: The V-shaped profile wires create slots that widen inwardly, ensuring that particles either pass through cleanly or are easily dislodged, minimizing blinding and maximizing throughput.

2.High Open Area: This design offers a significantly larger open area compared to perforated plate or wire mesh, leading to greater efficiency in filtration and separation.

3.Exceptional Strength and Durability: Constructed by welding V-shaped profile wires to support rods, wedge wire flat panels are incredibly robust, capable of withstanding heavy loads, high pressures, and abrasive materials – a crucial factor in mining applications.

4.Precise Slot Openings: Manufacturing precision allows for highly accurate and consistent slot sizes, critical for effective particle sizing, dewatering, and media retention.

5.Corrosion and Abrasion Resistance: Typically made from stainless steel (304, 316L, 904L, etc.) or other high-performance alloys, these panels offer excellent resistance to corrosion and wear, extending service life even in harsh environments.

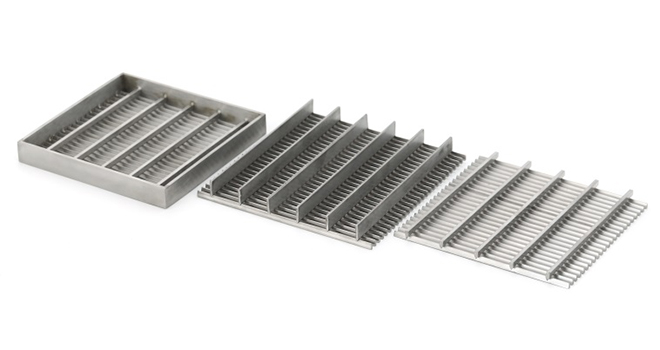

6.Customization: As a leading customized manufacturer, YUBO can tailor panel dimensions, slot sizes, wire profiles, materials, and frame constructions to your exact specifications.

Key Wedge Wire Flat Panel Applications – A Special Focus on the Mining Industry

While versatile, the robust nature of wedge wire flat panels makes them indispensable in the mining and mineral processing industries. Large mining operations continually seek solutions to enhance productivity, reduce downtime, and improve recovery rates – and our wedge wire products deliver.

1.Mining & Mineral Processing (Our Speciality for Large-Scale Operations):

- Dewatering Screens: Effectively remove excess water from slurries of coal, iron ore, sand, gravel, and other minerals. This reduces transport weight, improves handling, and prepares materials for further processing. Our custom dewatering wedge wire flat panels are designed for high G-force vibratory equipment, maximizing water removal.

-

Sizing and Classification: Precisely separate minerals and aggregates by size. The accurate slot openings ensure consistent product quality, crucial for meeting market specifications for valuable ores and materials.

-

Media Retention: Used in ion exchange systems, carbon-in-pulp (CIP) and carbon-in-leach (CIL) processes to retain expensive media (like activated carbon or resin beads) while allowing processed liquids or slurries to pass through. This prevents loss of valuable media and ensures process efficiency.

-

Trash Screens / Scalping Screens: Remove oversized debris, vegetation, and unwanted materials from process streams early on, protecting downstream equipment from damage and blockages.

-

Vibrating Screen Decks: Our heavy-duty wedge wire flat panels serve as robust screen surfaces on vibrating screens, enduring constant impact and abrasion while providing efficient separation.

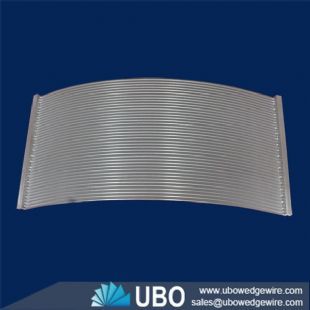

- Sieve Bends / DSM Screens: While often curved, the principles of wedge wire are applied here for fine particle separation and dewatering in mineral slurries. Flat panels can be incorporated into custom sieve bend housing designs.

Why Large Mining Companies Choose YUBO for Wedge Wire Flat Panels:

For major players in the mining sector, reliability isn't just a preference; it's a necessity. Downtime costs are enormous. YUBO understands this. We deliver:

* Unmatched Durability: Panels engineered for the extreme abrasion and heavy loads typical in mining.

* Optimized Performance: Custom designs that maximize throughput and separation efficiency for your specific ore type and process.

* Reduced Maintenance: Our non-clogging design and robust construction mean less frequent cleaning and replacement, saving valuable operational hours.

* Expert Consultation: We work with your engineers to design the perfect wedge wire flat panel application solution for your unique challenges.

2. Other Key Industrial Applications:

Beyond mining, wedge wire flat panels are vital in:

- Water Treatment & Wastewater Management: Intake screens, filter nozzles, underdrain systems, and sludge thickening.

-

Pulp & Paper: Fiber retention, dewatering, and screening applications.

-

Food & Beverage: Lauter tuns in breweries, juice extraction, and processing screens.

-

Chemical & Petrochemical: Reactor internals, catalyst support grids, and filtration elements.

- Architecture & Construction: Grates, vents, and decorative elements due to their strength and aesthetic appeal.

Partner with YUBO for Your Wedge Wire Flat Panel Needs

At YUBO, we are more than just a manufacturer; we are solution providers. As a foreign trade enterprise with a global reach, we are committed to delivering superior quality, customized wedge wire flat panels that enhance your operational efficiency and profitability.

Our expertise in wedge wire flat panel applications, particularly within the demanding mining industry, sets us apart. We understand the critical need for robust, reliable, and precisely engineered screening solutions.

Attention: Mining Industry Leaders and Procurement Managers!

Are you looking to:

- Improve dewatering efficiency in your mineral processing plant?

-

Reduce downtime caused by screen blinding or failure?

-

Optimize particle sizing for better recovery rates?

-

Source durable, custom-engineered wedge wire flat panels from a reliable global supplier?

Take the Next Step: Get Your Custom Quote Today!

Don't let inefficient screening hold back your mining operation. Contact YUBO today to discuss your specific wedge wire flat panel requirements. Our team of experts is ready to collaborate with you to design and manufacture the ideal solution that will withstand the toughest conditions and deliver unparalleled performance.

-

Call us on: 86-17363013056

- Visit our inquiry page:

- https://www.ubowedgewire.com/About/contact-us-22-1.htm

Let YUBO be your trusted partner for all your wedge wire flat panel application needs. We look forward to helping you achieve new levels of productivity and success.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient