sieve bend screen capacity

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

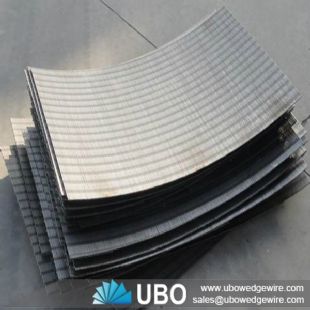

Sieve bend screen capacity refers to the maximum volume of material that the screen can process effectively without compromising its efficiency. This capacity depends on several factors, including the screen’s design, material properties, and operating conditions. By understanding these factors, industries can select the right screen and maximize throughput while maintaining optimal separation performance.

The sieve bend screens are very efficient in processing high capacities of material. Their capacity ranges from 40 gallons per minute (GPM) of slurry per foot of sieve bend width, all the way up to an impressive 300 GPM of slurry per foot of sieve bend width.

Factors Affecting Sieve Bend Screen Efficiency and Capacity

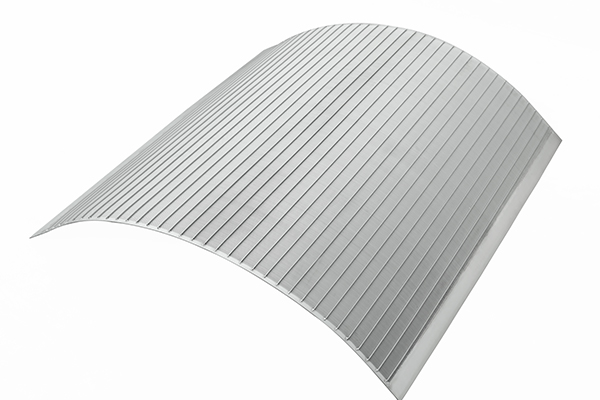

1. Screen Design

The design of the sieve bend screen significantly impacts its capacity. Key elements include:

Wedge Wire Profile: The use of wedge wire sieve bend screens ensures precise separation and high flow rates.

Open Area Percentage: A higher open area allows more fluid to pass through, increasing throughput.

Radius and Arc Length: Larger screens with extended arc lengths can handle greater volumes of material.

2. Material Characteristics

The type of material being processed plays a vital role. Factors such as particle size, shape, and density can influence the screen’s performance. For example:

Fine Particles: Require screens with smaller slot openings.

Slurry Consistency: High-viscosity slurries may reduce flow rates.

3. Operating Conditions

Optimal operating conditions are crucial for maximizing sieve bend screen capacity. Consider:

Feed Flow Rate: Ensuring the feed rate matches the screen’s capacity is critical for efficient separation.

Angle of Inclination: Proper screen angle improves material flow and prevents clogging.

Maintenance: Regular cleaning and inspection prevent blockages and extend the screen’s lifespan.

We can custom design various capacities of sieve bend screens according to your project needs.

Our sieve bends are widely used for water treatment, wastewater treatment, coal processing, and food and sugar industries. Customized for maximum screening efficiency.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient