sieve bend screen applications mineral processing wastewater and food Industries

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

In the world of industrial processing, efficient solid-liquid separation is not just an operational goal—it's a critical factor for profitability, sustainability, and product quality. From recovering valuable minerals to ensuring the purity of food products, the right screening technology can make all the difference. Among the most effective and elegant solutions is the sieve bend screen.

As a specialized manufacturer of custom sieve bend screens, Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as “YUBO”) has seen firsthand how this simple, yet powerful, technology transforms operations across diverse sectors. Unlike powered equipment like vibrating screens, the sieve bend screen operates with no moving parts and zero energy consumption, making it a cornerstone of modern, cost-effective processing.

This article will take a deep dive into the three primary industries where sieve bend screens deliver unparalleled value: Mineral Processing, Wastewater Treatment, and the Food & Beverage industry.

What Makes the Sieve Bend Screen So Effective?

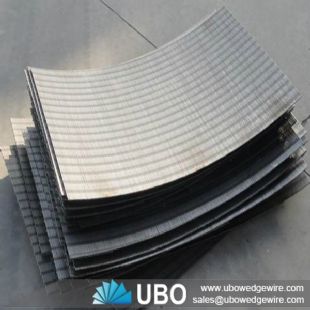

Before we explore the applications, let's understand why the sieve bend screen, also known as a wedge wire sieve bend or DSM screen, is so versatile. Its performance hinges on a few key design principles:

-

No Moving Parts: This means no energy costs, minimal maintenance, and a significantly longer operational lifespan compared to mechanical screens.

-

Non-Clogging Design: The screen surface is made of V-shaped wedge wires that are resistant to blinding and clogging. This ensures continuous, uninterrupted flow and consistent performance.

-

High Capacity & Efficiency: The curved profile of the screen, combined with the Coanda effect, allows it to handle high hydraulic loads and perform fine separations with remarkable efficiency.

- Customization: Every aspect—from the slot size and material (e.g., Stainless Steel 304, 316L) to the arc angle—can be tailored to a specific application, ensuring optimal results.

1. Revolutionizing Mineral Processing

The mining and mineral processing industry faces immense pressure to maximize recovery rates and minimize operational costs. Sieve bend screens are an indispensable tool in achieving these goals.

The Challenge in Mineral Processing:

Operators deal with massive volumes of slurries, where fine particles must be dewatered, classified, or recovered efficiently. Inefficient separation leads to product loss, high energy consumption in downstream dryers, and excessive wear on equipment.

How Sieve Bend Screens Provide the Solution:

-

Coal Fine Dewatering: In coal preparation plants, sieve bends are used to dewater fine coal slurries, recovering valuable product that would otherwise be lost to tailings ponds and reducing the moisture content before thermal drying.

- Particle Classification: They effectively classify materials by size in closed-circuit grinding operations. The precise slot opening allows undersized particles to pass through while oversized particles are returned for further grinding.

-

Media Recovery: In Dense Media Separation (DMS) circuits, sieve bend screens are essential for recovering valuable heavy media (like magnetite) from the product stream, drastically reducing operational costs.

- Trash Removal: They serve as robust scalping screens to remove tramp and oversized materials, protecting more sensitive downstream equipment like pumps and cyclones.

By integrating custom-designed sieve bend screens, mineral processing plants can significantly increase yield, reduce the load on centrifuges and filters, and lower overall energy consumption.

2. Enhancing Efficiency in Wastewater Treatment

Whether for municipal or industrial effluent, effective wastewater treatment is crucial for environmental compliance and operational sustainability. Sieve bend screens offer a reliable, low-maintenance first line of defense.

The Challenge in Wastewater Treatment:

Wastewater streams often contain high levels of suspended solids that can overload primary clarifiers, damage pumps, and increase the biological oxygen demand (BOD) and chemical oxygen demand (COD) of the effluent.

How Sieve Bend Screens Provide the Solution:

-

Primary Screening for Industrial Effluent: In industries like pulp & paper, tanneries, and textile manufacturing, sieve bend screens are used to remove a significant portion of suspended solids from the effluent before it enters the main treatment plant. This reduces chemical usage and sludge volume later on.

-

Municipal Wastewater Pre-treatment: As a fine screen at the headworks of a treatment plant, it can remove non-organic solids, protecting pumps, pipes, and other critical equipment from clogging and abrasion.

-

Sludge Thickening: Sieve bends can be used to dewater and thicken sludge, reducing its volume and making it easier and cheaper to handle, transport, and dispose of.

-

Byproduct Recovery: In facilities like poultry processing plants or fish canneries, sieve screens are used to recover valuable solids from the wastewater stream, turning a waste product into a potential revenue source (e.g., for animal feed).

For any facility looking for a cost-effective wastewater screening solution, the sieve bend is an ideal choice for reducing operational burdens and improving treatment outcomes.

3. Ensuring Purity and Yield in the Food & Beverage Industry

In the food and beverage industry, hygiene, product quality, and maximizing yield are non-negotiable. Sieve bend screens, constructed from food-grade stainless steel (SS 304/316L), are perfectly suited for these demanding environments.

The Challenge in Food Processing:

Processes often involve washing, separating, and clarifying liquids. Losing valuable product in wash water is costly, and inefficient separation can compromise the final product's quality and purity.

How Sieve Bend Screens Provide the Solution:

-

Starch Washing and Fiber Recovery: In corn wet milling, sieve bends are the industry standard for washing starch and separating it from fiber. Their high efficiency ensures maximum starch purity and yield.

-

Fruit & Vegetable Processing: They are used to separate juice from pulp, seeds, and skins. The gentle, static screening action preserves the quality of the juice without introducing unwanted solids.

-

Sugar Processing: In sugar mills, sieve bend screens effectively separate bagasse (sugarcane fiber) from raw juice, a critical step for clarifying the juice and preventing issues in evaporators.

-

Wash Water Recycling: By screening solids from wash water (e.g., from potato or vegetable washing), plants can recycle the water, significantly reducing their overall water consumption and wastewater output.

The hygienic, easy-to-clean design of a wedge wire sieve bend makes it an essential component for any modern, efficient food processing line.

Why Choose YUBO for Your Sieve Bend Screen Needs?

The true power of a sieve bend screen lies in its application-specific design. As a specialized manufacturer and global supplier, we don't just sell products—we engineer filtration solutions.

-

Complete Customization: We work directly with you to determine the ideal slot size, wire profile, arc angle, and housing design for your unique process requirements.

-

Premium Materials: YUBO build our screens from high-quality Stainless Steel 304, 316L, Duplex, and other alloys to ensure maximum durability, corrosion resistance, and compliance with industry standards.

-

Global Expertise: With extensive experience in foreign trade, YUBO understand the complexities of international logistics and provide comprehensive support to ensure your equipment arrives safely and on time.

Ready to Optimize Your Separation Process?

Whether you are looking to recover valuable minerals, reduce your wastewater treatment costs, or increase the yield of your food product, the sieve bend screen is a proven, reliable, and highly cost-effective solution.

Don't settle for a one-size-fits-all approach. Contact YUBO's expert engineers today for a free consultation. Let's discuss your application and design a custom sieve bend screen that will unlock new levels of efficiency for your operation.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient