ion exchange nozzle installation locations

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

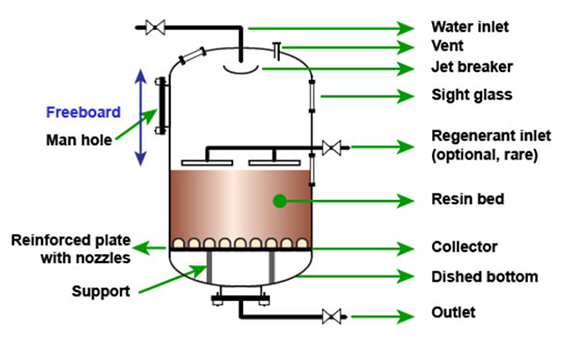

As a leading global manufacturer of high-performance ion exchange nozzles, we at Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as YUBO) understand that the effectiveness of any water treatment or chemical processing system hinges not just on the quality of its components, but also on their correct application. A frequently underestimated factor is the ion exchange nozzles installation position. Proper placement is critical for ensuring optimal flow distribution, efficient regeneration, minimal resin loss, and overall system longevity.

This article dives into the importance of correct nozzle installation positions within ion exchange vessels and related equipment, helping engineers, operators, and system designers maximize their system's performance and reliability.

Why is Ion Exchange Nozzle Installation Position So Critical?

Ion exchange nozzles (also known as strainer nozzles, filter nozzles, or underdrain nozzles) perform several vital functions:

1.Retaining Media: They prevent the costly loss of valuable ion exchange resin or other filter media.

2.Distributing Flow: They ensure uniform flow of liquids (during service cycles) and gases/liquids (during backwash/regeneration) across the entire media bed.

Incorrect installation positioning directly compromises these functions, leading to:

- Channeling: Uneven flow paths through the resin bed, reducing treatment efficiency and leading to premature exhaustion.

- Resin Loss: Gaps or improper sealing allowing media to escape, increasing operational costs.

- Poor Backwash Efficiency: Inability to properly lift and clean the resin bed, causing fouling and reduced capacity.

- Increased Pressure Drop: Non-uniform flow causing higher resistance and energy consumption.

- Potential Mechanical Damage: Incorrect stress on nozzles or vessel internals.

Common Ion Exchange Nozzle Installation Locations and Considerations:

Understanding where nozzles are typically installed helps clarify why specific positioning is crucial:

1.Underdrains / Collector Plates (Bottom Distribution/Collection):

- Position: Fitted into a nozzle plate at the bottom of the vessel.

- Function: To collect treated liquid uniformly during the service cycle and distribute backwash water/air effectively during regeneration.

-

Key Considerations:

1.Spacing: Nozzles must be spaced correctly (often in a specific pattern like triangular or square pitch) to ensure complete coverage and prevent dead zones. Manufacturer recommendations and process calculations dictate optimal spacing.

2.Evenness: The nozzle plate must be level, and nozzles installed perpendicular to ensure consistent flow profiles.

3.Sealing: Proper sealing (using gaskets or specific thread designs) prevents leakage between the nozzle and the plate.

2.Header-Lateral Systems (Distribution/Collection):

- Position: Nozzles are installed along lateral pipes connected to a central header pipe (either at the top for distribution or bottom for collection).

- Function: Similar to underdrains, but often used in larger vessels or specific process configurations.

-

Key Considerations:

1).Orientation: Nozzle slots or openings must be oriented correctly (often facing downwards for collectors, specific angles for distributors) to achieve the desired flow pattern and prevent plugging.

2).Lateral Spacing & Length: The design of the header-lateral system itself (pipe diameters, number of laterals, nozzle spacing along the laterals) is critical for hydraulic balance.

3).Structural Support: Ensuring the header-lateral system is adequately supported to handle the weight and flow forces.

3.Intermediate Plates (e.g., Counter-Current Regeneration):

- Position: Installed on plates within the vessel, often separating different media types or creating specific regeneration zones.

- Function: To collect/distribute regenerant chemicals or intermediate rinse water.

- Key Considerations: Similar spacing, orientation, and sealing rules apply as for underdrains, ensuring precise chemical delivery without disturbing adjacent media layers.

4.Outlet/Inlet Distributors:

- Position: Sometimes used directly on vessel inlet or outlet piping, especially in smaller systems or as polishers.

- Function: Primarily media retention.

- Key Considerations: Ensuring the nozzle can handle the full flow rate and pressure without excessive pressure drop or media escape.

5.Resin Traps:

- Position: Installed in downstream piping after the main ion exchange vessel.

- Function: As a final safety measure to catch any resin that might escape the main vessel due to upset conditions or primary nozzle failure.

- Key Considerations: Must be positioned for easy inspection and cleaning. Sized to capture target particle size without causing excessive pressure drop during normal operation.

Partnering with YUBO for Optimal Nozzle Solutions

Choosing the right nozzle is only half the battle; ensuring it's installed correctly is paramount. At [Your Company Name], we don't just manufacture high-quality ion exchange nozzles from durable materials like Stainless Steel; we provide expertise.

- Application Support: We help customers select the appropriate nozzle type, slot size, and material for their specific process conditions.

- Design Assistance: We can offer guidance on recommended installation patterns, spacing, and orientation based on vessel size and flow requirements.

-

Quality Assurance: Our nozzles are manufactured to strict tolerances, ensuring consistent performance and reliable fitting.

- Global Reach: As experienced foreign trade operators, we efficiently supply our products worldwide, meeting international standards.

Get Expert Advice on Your Ion Exchange Nozzle Installation

Optimizing your ion exchange system starts with the fundamentals. Don't let improper nozzle installation compromise your process efficiency and increase operating costs.

Are you designing a new system, troubleshooting an existing one, or looking to upgrade your ion exchange nozzles?

Contact YUBO today! Our team of experts is ready to discuss your specific requirements and help you determine the optimal ion exchange nozzle installation position and product selection for your application.

- Visit our Product Page: https://www.ubowedgewire.com/Filter_Nozzle/filter-nozzles-for-ion-exchange-132-1.htm

- Request a Quote: https://www.ubowedgewire.com/About/contact-us-22-1.htm

- Email Us: sales@ubowedgewire.com

- Call Us: Tel/Wechat/Whatsapp:86-173-6301-3056

By focusing on details like proper nozzle installation, you ensure the reliability and cost-effectiveness of your operations.

Trust YUBO as your partner in high-performance fluid handling solutions.

We are a stable supplier of ion exchange nozzles. We provide custom design services.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient