industrial sand filters underdrain filter nozzle systems

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

In industrial water treatment and liquid processing, the performance of your sand filters is non-negotiable. Poor filtration can lead to downstream equipment damage, product contamination, and costly operational shutdowns. While the filter media gets a lot of attention, the true heart of a high-performance sand filter lies beneath the surface: the underdrain filter nozzle system.

For plant managers, process engineers, and procurement specialists seeking to upgrade existing sand filters or specify new vessels, understanding this system is crucial. This guide provides the expert knowledge you need to make an informed decision and ensure your filtration process is efficient, reliable, and cost-effective.

What is an Underdrain Filter Nozzle System?

An underdrain filter nozzle system for industrial sand filters is an engineered assembly at the bottom of a filter vessel. It has two primary functions:

1.Uniform Collection: During the filtration cycle, it collects the filtered water (filtrate) evenly across the entire surface area of the filter bed.

2.Uniform Distribution: During the backwash cycle, it distributes the flow of backwash water and air scour evenly to dislodge trapped contaminants and clean the entire filter bed.

This system replaces older, less efficient methods like pipe laterals, which are prone to creating "dead zones" and uneven flow, leading to poor filter performance.

The Problem with Inefficient Underdrains: Are You Facing These Issues?

If your sand filters are underperforming, the culprit is often a poorly designed or failing underdrain. Common symptoms include:

1.Media Loss: Finding sand or filter media in your downstream piping.

2.Channeling: Water creating preferential paths through the filter bed, leaving large portions of the media unused.

3.Increased Backwash Frequency: Needing to clean the filters more often, wasting water, energy, and time.

4.Poor Filtrate Quality: Failing to meet the required purity standards for your process water.

A modern filter nozzle system is the definitive solution to these problems.

Core Components of a High-Efficiency System

A robust system is built on two key components working in harmony:

1.The Nozzle Plate: A solid plate, typically steel or fiberglass, that is installed above the bottom dished end of the vessel. It is drilled and tapped to accept the filter nozzles in a precise pattern. This plate provides a strong, level base for the entire media bed.

2.The Filter Nozzles: These are the critical components threaded into the nozzle plate. They are responsible for retaining the media while allowing water to pass through their engineered slots. They come in various designs, materials, and slot sizes to suit specific applications.

Choosing the Right Filter Nozzle: Material and Design Matter

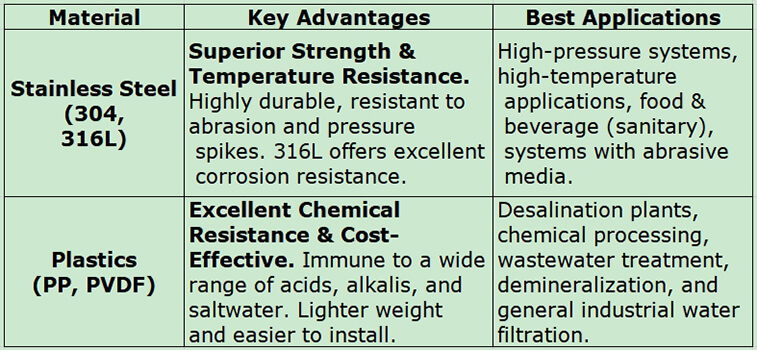

Selecting the correct nozzle is the most important step. Your choice will depend on temperature, pressure, chemical compatibility, and the type of media being used.

Material Selection: Stainless Steel vs. Engineering Plastics

Design: Why Wedge Wire Nozzles Offer an Advantage

While various plastic nozzle designs are effective, wedge wire screen nozzles (typically made of stainless steel) offer a distinct advantage in demanding situations. Their unique V-shaped profile creates a continuous slot that is highly resistant to clogging and provides a greater open area, improving flow characteristics and backwash efficiency.

Need help with your sand filter underdrain design? Our engineers can analyze your process requirements and recommend the optimal nozzle type and material. [Contact Us]

The Key to Longevity: Effective Backwashing

A properly designed underdrain filter nozzle system makes backwashing dramatically more effective. The process typically involves:

1.Air Scour: Compressed air is forced up through the nozzles, creating violent agitation that scrubs the media grains and breaks up compacted dirt.

2.Water Backwash: A high-velocity flow of water is then sent upwards, fluidizing the entire media bed and carrying the dislodged contaminants out to drain.

The uniform distribution provided by the nozzles ensures no part of the filter bed is left uncleaned, restoring the filter to peak performance with minimal water consumption.

How to Specify an Underdrain System for Your Project

When requesting a quote or discussing your project with a supplier, be prepared to provide the following information:

1.Vessel Diameter: The internal diameter of your sand filter vessel.

2.Flow Rate: Both the service (filtration) flow rate and the desired backwash flow rate.

3.Filter Media Specifications: The type of media (sand, anthracite, garnet) and, most importantly, its effective size and uniformity coefficient. This determines the required nozzle slot size.

4.Operating Conditions: The pressure, temperature, and chemical composition of the liquid being filtered.

Pro Tip: The nozzle slot size should be selected to be approximately 50-70% of the smallest media grain size to ensure reliable retention without causing excessive pressure drop.

Partner with a Global Expert in Solid-Liquid Separation

Upgrading your industrial sand filters with a high-performance underdrain filter nozzle system is an investment in operational reliability and efficiency. It reduces maintenance, saves water and energy, and ensures the consistent quality of your process water.

As a specialized international supplier, we provide complete underdrain solutions for clients across the globe in industries from power generation and mining to petrochemicals and municipal water treatment.

Take the next step towards optimizing your filtration process.

1.Get a Technical Consultation: Discuss your specific application with our engineering team.

2.Receive a Custom Quotation: We will provide a detailed quote based on your vessel and process requirements.

3.Benefit from Global Shipping: We have the logistics experience to deliver your system anywhere in the world.

Contact us today to request your free quote and ensure your industrial sand filters operate at peak performance.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient