how to choose wedge wire flat panel?

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

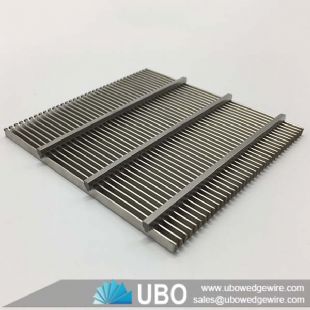

In the demanding world of industrial separation and filtration, choosing the right wedge wire flat panel is critical for operational efficiency, longevity, and cost-effectiveness. Whether you're processing minerals, filtering liquids, dewatering sludge, or screening aggregates, the wrong panel can lead to premature failure, blinding, reduced throughput, and unexpected downtime. As a leading wedge wire manufacturer, Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as “YUBO”) understand these challenges intimately. This guide empowers you with the knowledge to select the optimal wedge wire flat panel for your specific application.

Key Factors to Consider When Selecting a Wedge Wire Flat Panel:

1.Application & Process Parameters:

1)Media Being Processed: What are you filtering or separating? (e.g., sand, gravel, coal, biomass, pulp, sugar juice, wastewater sludge, chemicals). Consider particle size distribution, abrasiveness, corrosiveness, and moisture content.

2)Flow Rate & Capacity: What volume needs to be processed per unit time? This impacts panel size and slot opening selection.

3)Operating Pressure & Load: Will the panel be under significant static load (e.g., deep beds of material) or dynamic pressure (e.g., high-pressure filtration)? This determines required strength.

4)Temperature Range: What temperatures will the panel be exposed to? This affects material selection.

5)Process Environment: Is it wet, dry, acidic, alkaline, or involve solvents? This heavily influences corrosion resistance needs.

2.Slot Size (Aperture):

This is arguably the most crucial specification. The slot size determines the size of particles that will pass through or be retained.

1)Rule of Thumb: The slot size should be slightly smaller than the minimum particle size you want to retain or slightly larger than the maximum particle size you want to pass.

2)Consider: Slot sizing needs to account for potential blinding (blockage) – sometimes a slightly larger slot than theoretically needed is chosen for better flow and easier cleaning.

3)Precision Matters: Reputable manufacturers offer precise slot openings, often ranging from 0.02mm (0.0008") up to 3mm (0.118") or more, with tight tolerances.

3.Material Selection:

1)Stainless Steel (Most Common):

304 / 304L: Good general corrosion resistance, cost-effective for many water and less aggressive chemical applications.

316 / 316L: Superior corrosion resistance to chlorides and many chemicals compared to 304. Ideal for marine, food, pharmaceutical, and more aggressive environments.

Duplex (e.g., 2205): Excellent strength and superior corrosion resistance, especially to pitting and stress corrosion cracking. Used in demanding offshore, chemical, and pulp & paper applications.

Super Austenitic (e.g., 904L): For highly corrosive environments like strong acids.

2)Carbon Steel: Lower cost, used for non-corrosive, high-wear applications like coarse aggregate screening. Often coated or galvanized.

3)Specialty Alloys: Nickel alloys (Hastelloy, Monel), titanium, or other exotics available for extreme corrosion or temperature conditions.

4)Consider: Match the material precisely to your process chemistry and temperature to avoid costly failures.

4.Structural Specifications:

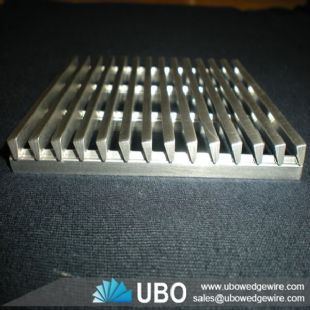

Wire Profile (V-Wire Shape & Dimensions): The shape (typically trapezoidal or triangular) and the width of the wire's base impact strength, open area, and flow characteristics.

1)Support Rod Diameter & Spacing: Thicker rods and closer spacing significantly increase panel strength and load-bearing capacity, essential for high-pressure or heavy material applications. Thinner rods/wider spacing offer higher open area for flow.

2)Panel Thickness: Directly relates to overall strength and rigidity.

3)Weld Strength & Integrity: Full, continuous welds between the V-wires and support rods are vital for structural integrity and longevity. Poor welding leads to premature failure.

5.Surface Finish & Treatments:

1)Smooth Finish: Standard for most applications, minimizes friction and potential material buildup.

2)Polished Finish: Crucial for food, pharmaceutical, and bio applications for cleanability and preventing bacterial growth.

3)Special Coatings: Epoxy, rubber, or polyurethane coatings can be applied for enhanced corrosion resistance, abrasion resistance, noise reduction, or to prevent blinding in sticky materials.

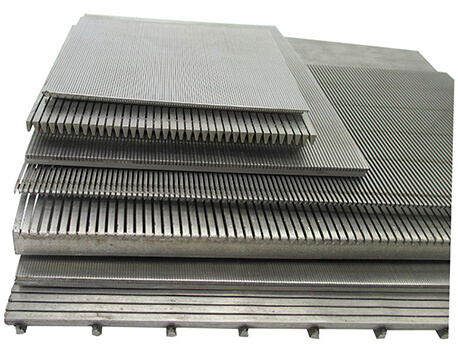

6.Dimensions & Configuration:

1)Panel Size: Must fit precisely into your existing equipment (screeners, filter presses, sieve bends) or be designed for new machinery.

2)Edge Details: Flanged edges, bolt holes, or specific mounting provisions are often required for secure installation. Specify these clearly.

3)Flat or Curved: While "flat panels" are common, wedge wire can be manufactured to specific curves (e.g., for sieve bends).

Why Partner With YUBO for Your Wedge Wire Flat Panels?

Selecting the right wedge wire panel isn't just about specifications; it's about partnering with a manufacturer who understands your process and delivers reliable, high-performance wedge wire flat panels solutions.

1.Unparalleled Expertise: YUBO has more than 10 years of experience crafting wedge wire solutions for diverse global industries.

2.Precision Manufacturing: State-of-the-art facilities ensuring consistent slot accuracy, superior weld integrity, and dimensional perfection.

3.Extensive Material Range: From standard 304SS to exotic alloys, we provide the optimal material for your environment.

4.Customization is Key: We don't just sell standard sizes; we engineer panels tailored to your exact application requirements, dimensions, and performance needs.

5.Quality Assured: Rigorous quality control processes at every stage guarantee panels that perform and last.

6.Global Support: Dedicated technical support to help you select, install, and maintain your wedge wire panels.

Don't Leave Your Filtration or Separation Performance to Chance!

Choosing the correct wedge wire flat panel is an investment in the efficiency and profitability of your operation. By carefully considering your application, slot size, material, structural needs, and configuration, you can ensure optimal performance and longevity.

Ready to Select the Perfect Wedge Wire Flat Panel?

Contact the experts at YUBO today! Our technical team is ready to discuss your specific application challenges and recommend the ideal wedge wire solution.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient