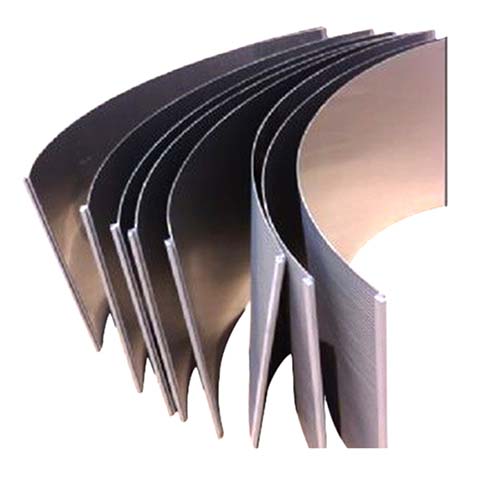

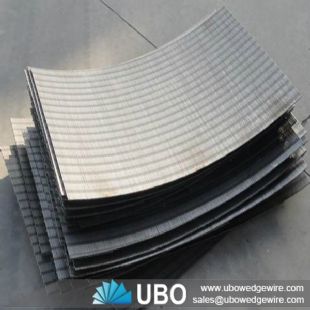

Working principle and application of Wedge Wire DSM Screen

1, working principle

The curved screen uses a pumping fluid to tangentially spray into the curved screen surface and separates the solid matter and the liquid by centrifugal force and gravity. At the same time, the filter is cleaned by the rolling of the separated solid matter and the hydraulic flushing action of the liquid, thereby purifying the net. During the flow of the fluid along the downward direction of the screen, the contact surface of the solid object and the filter screen is constantly changed, which is favorable for the uniform outflow of water, and can make the specific gravity of the fluid larger, and the fine sand impurities smaller than the mesh have the opportunity to escape from the solid matter. It is excluded as the water passes through the filter.

2. The Wedge Wire DSM Screen is an economical and practical solid-liquid separation equipment. In the paper industry, it can be used in the following applications:

White water fiber recycling

Slurry concentration

Purification of spray water and seal water

Long and short fiber grading

Fiber/filler separation

White water filtration, sewage treatment

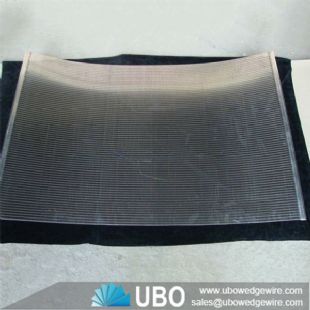

UBO Company is a professional supplier in China. It is always committed to study, design and produce filter elements. Now its products include wedge wire filter element, filter nozzle, cylindrical filter element, pleated filter element, cone filter.