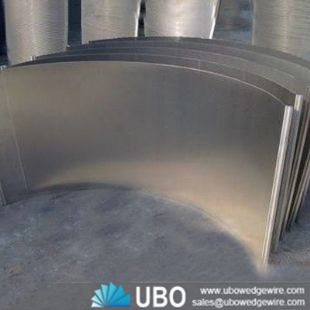

Low carbon stainless steel side Hill sieve bend screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Screen |

| Application: | the sea water transforms into the industrial water and life use water desalination treatment, running water treatment |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Low carbon stainless steel side Hill sieve bend screen

Side Hill Screen are also known as DSM screens, Sieve bends, and sieve bend as a static sizing screen having ten times greater capacity than conventional vibrating screens.

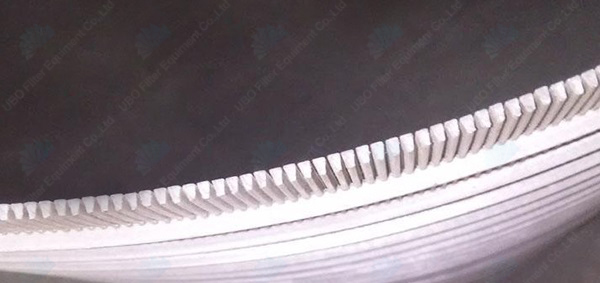

As slurry flows down the screen each wedgewire's sharp leading edge slices away a thin layer of water and small-particle solids. Larger particles continue down the screen surface, with much of the liquid removed. Separation size is considerably smaller than screen openings, usually about one half the opening size

Applications for Low carbon stainless steel side Hill sieve bend screen:

It can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters,the ethyl alcohol and so on the organic solution recycling filter.

Features for Low carbon stainless steel side Hill sieve bend screen:

Low Headroom - only 1.1 metres (44") tall for the 900 mm arc length unit.

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

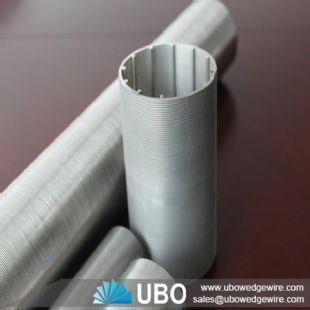

Specifications of Low carbon stainless steel side Hill sieve bend screen:

|

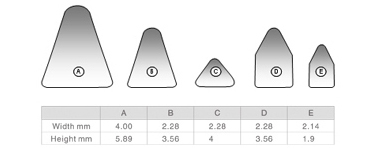

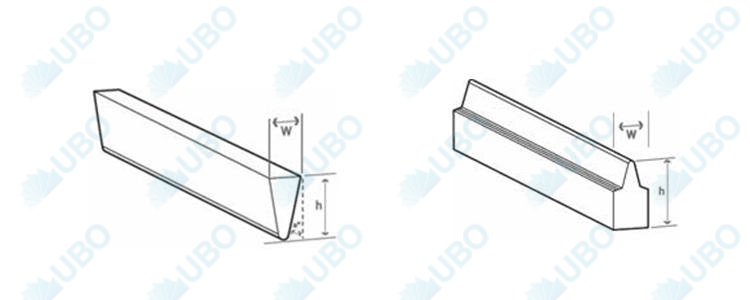

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of Low carbon stainless steel side Hill sieve bend screen: