Welded wire screen grating for filteration

| Category: | Wedge Wire Screen Panel |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Welded wire screen grating for filteration

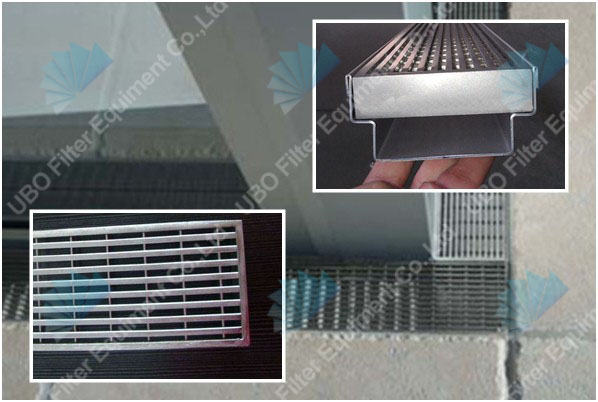

The Welded wire screen grating is the most important part to connect the system of drainage channels and the flooring.

As the most important part of the drainage system in the house, its performance directly effect the quality of the indoor air, and it is also very important to control the peculiar smell of the bathroom.

The Welded wire screen grating is mainly used in bathroom, kitchen, washroom, swimming pool or other wet rooms.

Advantages of Welded wire screen grating for filteration

1>.Drainage fast , always keep the bathroom dry and clean , enhance the level of non-slip surface

2>.Increase three dimensional sense of space ,do not use stone to separate dry and wet areas again ,and don't use any other Stainless Steel Linear Drain

3>.Save the time of construction , using the drainage of same gradient, construction of simple ,maintain tile integrity and beautiful appearance .

4>.Security increased ,it is a trouble free access for some people whose action is inconvenience as it do not need the stone to separate dry and wet areas

5>.Beautiful appearance ,to be part of the bathroom , become a kind of elegant decoration

Application of Welded wire screen grating for filteration

Welded wire screen grating is widely used in filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens, lauter tun screens, many other liquids, solids separation applications.

Advantages of Welded wire screen grating for filteration

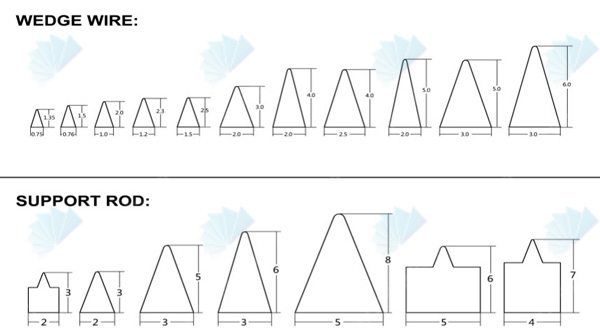

A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer)

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

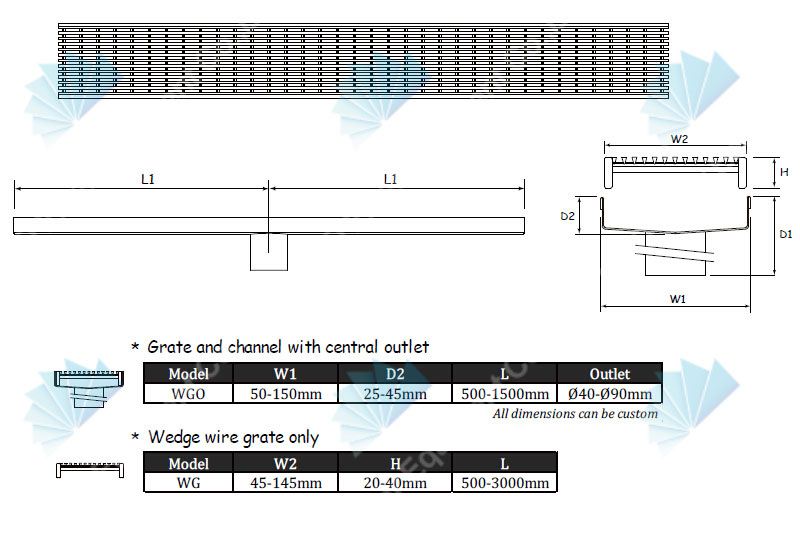

Specifications of Welded wire screen grating for filteration:

Slot size (mm): 0.025mm 0.10, 0.15, 0.2, 0.25, 0.30-3mm

Open area: up to 60%

Material: low carbon, low carbon galvanized steel (LCG) steel , stainless steel (304 etc.) Lengths up to 6 meters

Diameter: ranging from 25 to 800mm

End connection: plain beveled ends for butt welding or threaded

Material: Low Carbon Galvanized ( LCG ) and Stainless Steel (SS)

Slot (mm): 0.025 0.1、0.25、0.50、0.75、1.00、1.50、2.00、3.00 and so on.

Packaging and Transportation of Welded wire screen grating for filteration: