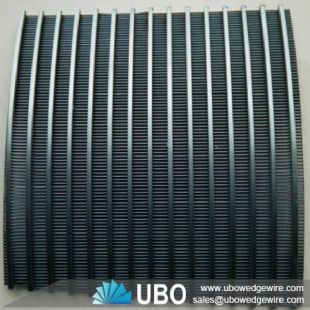

welded sieve bend wedge wire screen for mining filtration

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 302,304,304L,316,316L |

| Properties: | wedge wire screen |

| Application: | water treatment ,oilfield,mining,water well,food,industry,filtration |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of welded sieve bend wedge wire screen for mining filtration

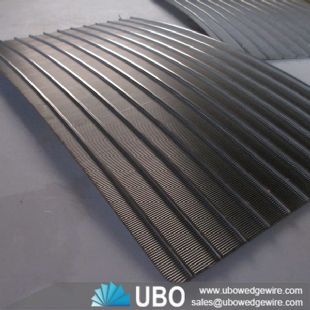

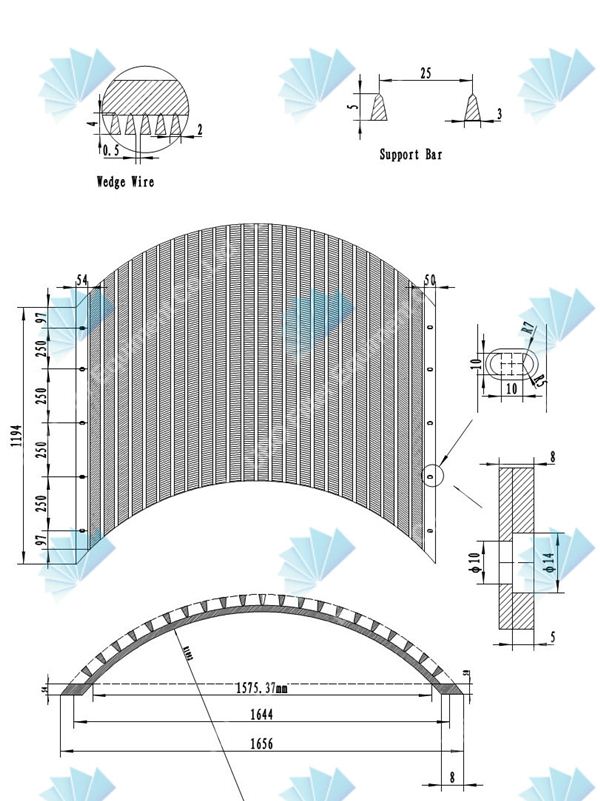

The welded sieve bend wedge wire screenof a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width). The chart below shows typical dewatering capacities in US gallons per minute (GPM) per foot of screen width. Actual capacity varies depending on the feed content and desired efficiency.

Screening efficiency and solids capacity are directly related to the length (arc length). Longer arc lengths should be considered for feed containing a high percentage of solids.

Features of welded wedge wire sieve bend screen for mining filtration

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

Flexible Design - we can supply units with any features you may require.

Applications of welded wedge wire sieve bend screen for mining filtration

welded wedge wire sieve bend screen are utilized as conveyor and auger screening media in dewatering and draining applications. Wedgewire conveyor screens usually have axial wires and are half cylinders. Other configurations are also produced.

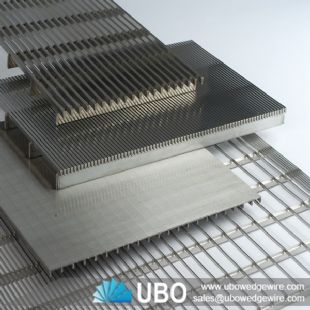

Specifications of welded sieve bend wedge wire screen for mining filtration:

|

welded wedge wire sieve bend screen |

|

|

Material: |

Low carton, low carton galvanized steel (LCG), steel treated with plastic spraying, stainless steel (304,316etc.) |

|

Wedge Wire (mm): |

Width : 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

|

Support Rod (mm): |

Width : 2.30 3.00 3.30 3.70 |

|

Height : 2.70 3.60 4.70 5.60 6.30 |

|

|

Width: |

from 1 inch -----45 inch. |

|

Length: |

Max 6 meters. |

|

Slot size |

Slot size |

|

Radian: |

15º,30º,45º as your request |

Packaging and Transportation of welded sieve bend wedge wire screen for mining filtration: