Reversed Continuous Slot Wire Wrapped Screen Cylinder

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen |

| Application: | mineral processing,coal processing,food processing,water treatment,petrochemical industry |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Reversed Continuous Slot Wire Wrapped Screen Cylinder

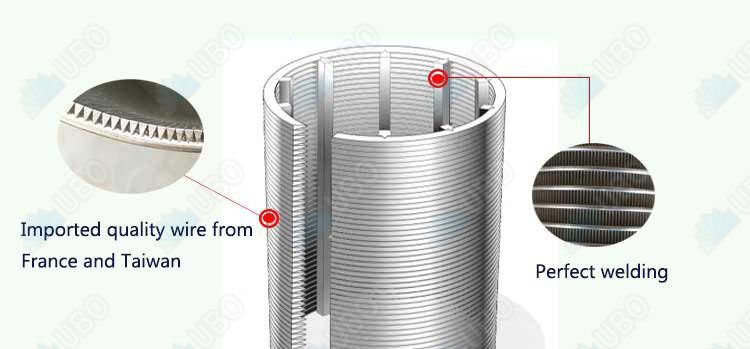

Reversed Continuous Slot Wire Wrapped Screen Cylinder is also called wedge wire cylinder. It is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding.

Features for Reversed Continuous Slot Wire Wrapped Screen Cylinder:

1) Continuous slot screens, stronger and more durable

2) More open area, very precise openings

3) Virtually non-clogging and reduce media abrasion

4) Easier installation and long-term operating and cost benefits

Applications for Reversed Continuous Slot Wire Wrapped Screen Cylinder:

It is widely used in mineral processing, coal processing, food processing, water treatment, petrochemical industry, architecture industry, as well as many other applications involving liquid & solids separation.

Advantages of Reversed Continuous Slot Wire Wrapped Screen Cylinder:

1) A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2) A uniform and efficient well development due to the continuous slot opening.

3) Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

4) Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Specifications of Reversed Continuous Slot Wire Wrapped Screen Cylinder:

|

Basepipe OD (in)

|

Perforations per Foot

|

Basepipe Hole Size (in)

|

Open Area of Basepipe Holes (in2/ft)

|

Wrap Wire Size Keystone (in)

|

Rib Wire Size Round (in)

|

Maximum OD (in)

|

|

1.05

|

54

|

0.312

|

4.14

|

0.09*0.09

|

0.125

|

1.489

|

|

1.315

|

66

|

0.312

|

5.06

|

0.09*0.09

|

0.125

|

1.726

|

|

1.66

|

78

|

0.312

|

5.98

|

0.09*0.09

|

0.125

|

2.126

|

|

1.90

|

42

|

0.375

|

4.63

|

0.09*0.09

|

0.125

|

2.387

|

|

2.063

|

42

|

0.375

|

4.63

|

0.09*0.09

|

0.125

|

2.55

|

|

2.375

|

54

|

0.375

|

5.96

|

0.09*0.09

|

0.125

|

2.86

|

|

2.875

|

66

|

0.375

|

7.28

|

0.09*0.09

|

0.125

|

3.362

|

|

3.25

|

78

|

0.375

|

8.61

|

0.09*0.09

|

0.125

|

3.737

|

|

3.50

|

78

|

0.375

|

8.61

|

0.09*0.09

|

0.125

|

3.987

|

|

4.00

|

90

|

0.375

|

9.94

|

0.09*0.09

|

0.125

|

4.487

|

|

4.50

|

102

|

0.375

|

11.26

|

0.09*0.09

|

0.125

|

5.001

|

|

5.00

|

114

|

0.375

|

12.59

|

0.09*0.09

|

0.125

|

5.506

|

Packaging and Transportation of Reversed Continuous Slot Wire Wrapped Screen Cylinder: