what is the capacity of the sieve bend screen

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

As a leading manufacturer of sieve bend screens for the global market, one of the most common questions Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as YUBO) receive is: "What is the capacity of your sieve bend screen?"

While it seems like a simple question, the answer is nuanced. The capacity of a sieve bend screen isn't a single, fixed number. It's a dynamic performance metric that depends on a combination of screen design, application specifics, and material characteristics.

Understanding these factors is critical to selecting the right screen to maximize your operational efficiency, whether you're in mining, food processing, wastewater treatment, or the pulp and paper industry. This guide will break down everything you need to know about sieve bend screen capacity.

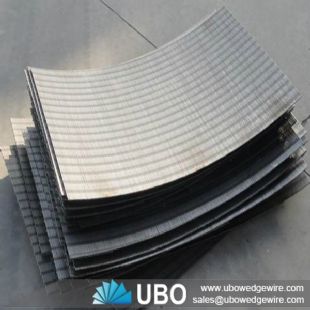

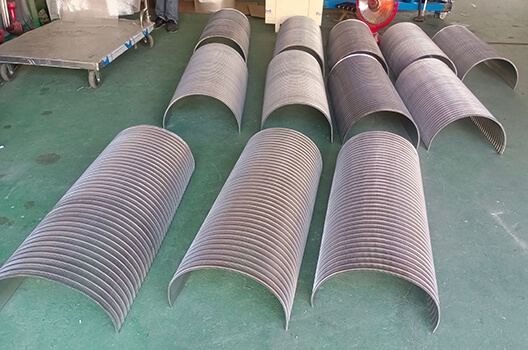

First, What is a Sieve Bend Screen?

A sieve bend screen, also known as a DSM screen or a static screen, is a highly efficient dewatering and classification device. It consists of a curved screen panel made of V-shaped wedge wires. As a slurry is fed onto the top of the screen, the curved surface causes a thin layer of water to be "shaved off" by the sharp edge of each wire, passing through the slots while the oversized solids slide down the screen's surface.

This simple, motor-less design makes it a reliable and low-maintenance solution for solid-liquid separation.

Defining "Capacity": Hydraulic vs. Solids Loading

When we talk about "capacity," we're really talking about two different, but related, metrics:

1.Hydraulic Capacity (Flow Rate): This refers to the maximum volume of liquid (slurry) that can pass through the screen in a given time. It's typically measured in gallons per minute (GPM), cubic meters per hour (m³/hr), or liters per second (L/s).

2.Solids Loading Capacity: This refers to the amount of solid material the screen can effectively process and separate from the liquid. It's usually measured in tons per hour (TPH) or kilograms per hour ( kg/hr ).

Your ideal screen will be one that balances both hydraulic and solids loading capacity for your specific process.

7 Key Factors That Determine Sieve Bend Screen Capacity

The performance of a sieve bend screen is not determined by its size alone. It is a result of several interacting factors.

1. Slot Size (Aperture)

This is the most critical factor. The size of the opening between the wedge wires directly controls the separation size.

- Smaller Slots (e.g., 0.25mm): Provide finer separation but have a lower hydraulic capacity. They are ideal for capturing very fine particles.

- Larger Slots (e.g., 2.0mm): Allow for a much higher flow rate but will let smaller solids pass through.

2. Screen Width

A wider screen provides more surface area for separation. As a general rule, doubling the screen width will approximately double the capacity, assuming all other factors remain constant.

3. Arc Length and Angle

The length and curvature of the screen determine the residence time—how long the material stays on the screen surface. A longer arc provides more time for dewatering, which can be crucial for slurries that release water slowly.

4. Wedge Wire Profile

The shape of the V-shaped wire influences flow dynamics and resistance to blinding (clogging). At YUBO, we can customize the wire profile to optimize the balance between open area, wear life, and dewatering efficiency for abrasive or sticky materials.

5. Material Characteristics

The properties of the slurry you are processing have a massive impact:

-

Percent Solids: Higher solids concentration reduces hydraulic capacity.

- Particle Size Distribution (PSD): The range of particle sizes in your feed affects separation efficiency.

- Viscosity & Stickiness: More viscous or sticky materials (like certain food starches or clays) flow slower and require specific design considerations.

6. Feed Method

How the slurry is introduced to the screen is vital. A properly designed headbox or feed nozzle ensures the slurry is distributed evenly across the full width of the screen at the correct velocity. Poor distribution will lead to channeling and drastically reduced capacity.

7. Orientation and Angle of Installation

While sieve bends are static, their installation angle can be fine-tuned to either increase residence time (for better dewatering) or speed up solids discharge (for higher throughput).

How to Estimate Sieve Bend Screen Capacity

While a precise calculation requires expert analysis, a basic formula for estimating hydraulic capacity (Q) is:

Q (m³/hr) ≈ C × W

Where:

- Q = Hydraulic Capacity in cubic meters per hour.

-

C = A "Capacity Factor" that typically ranges from 1.5 to 2.0. This factor depends heavily on the slot size and application. For example, a 0.5mm slot might have a C-factor of 1.75 m³/hr per 100mm of screen width.

- W = The screen width in units of 100mm.

Important: This is a rough estimation. For an accurate capacity calculation for your specific application, it is essential to consult with an experienced sieve bend screen's manufacturer YUBO.

Partner with the Experts for Guaranteed Performance

Choosing the wrong sieve bend screen can lead to production bottlenecks, poor separation efficiency, and higher operational costs. Don't leave it to guesswork.

At YUBO, we don't just sell products; we provide engineered solutions. Our team of experts will work with you to analyze your process requirements, including:

-

Your slurry's characteristics.

-

Your desired flow rate and separation goals.

-

Your existing plant infrastructure.

Based on this data, we will design and manufacture a custom sieve bend screen with the precise slot size, dimensions, and material (e.g., Stainless Steel 304, 316L, 2205) to deliver the exact capacity you need.

Ready to maximize your separation efficiency?

Let us help you determine the perfect sieve bend screen capacity for your operation. Contact our engineering team today for a free consultation and a no-obligation quote.

[Click https://www.ubowedgewire.com/About/contact-us-22-1.htm to Get Your Free Quote and Capacity Consultation]

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient