the purpose of the centrifuge basket screen

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

In the world of industrial processing, achieving efficient and precise separation of solids from liquids is paramount. At the heart of many such operations lies a critical component: the Centrifuge Basket Screen. If you're involved in industries like mining, chemical processing, food and beverage, or wastewater treatment, understanding the purpose of this vital part can significantly impact your operational efficiency and product quality.

As a leading international manufacturer of high-performance screen baskets, we at Hebei YUBO Filtration Equipment Co.,Ltd.(Hereinafter referred to as “YUBO”) often get asked about the fundamental role these components play. So, let's dive in.

The Core Function: Precision Solid-Liquid Separation

The primary purpose of a Centrifuge Basket Screen (also known as a centrifugal screen or screen basket) is to act as a sophisticated filter medium within a centrifuge. Here's how it works:

1.Slurry Introduction: A mixture of solids and liquids (slurry) is fed into the rotating centrifuge basket.

2.Centrifugal Force: The rapid rotation of the basket generates powerful centrifugal forces, many times greater than gravity.

3.Separation: This force flings the denser solid particles outwards against the inner wall of the Centrifuge Basket Screen. The liquid phase, being less dense, passes through the precisely engineered openings (slots or perforations) of the screen.

4.Collection: The separated solids are retained on the screen surface and are subsequently discharged, while the clarified liquid (filtrate) is collected separately.

Essentially, the Centrifuge Basket Screen is the gatekeeper, meticulously allowing liquids to pass while securely retaining solids, leading to effective dewatering, clarification, or classification.

Key Benefits of Using a High-Quality Centrifuge Basket Screen:

The effectiveness of your entire centrifugation process hinges on the quality and design of your screen basket. A well-designed Centrifuge Basket Screen offers numerous advantages:

- Enhanced Purity & Product Quality: Precise slot or hole sizes ensure minimal solids carry-over into the liquid phase, and minimal liquid retention in the solid cake, leading to higher purity products.

-

Increased Efficiency & Throughput: Optimized screen design allows for faster dewatering and higher processing capacities, boosting overall plant productivity.

-

Reduced Operational Costs: Durable screens mean longer operational life, less frequent replacements, and reduced downtime. Efficient dewatering can also lower subsequent drying costs.

-

Versatility Across Industries: Centrifuge Basket Screens are indispensable in diverse applications, including:

1)Mining & Minerals Processing: Dewatering coal fines, mineral concentrates (e.g., potash, salt).

2)Chemical & Petrochemical Industries: Separating crystals, polymers, and other chemical compounds.

3)Food & Beverage Processing: Starch extraction, sugar refining, juice clarification.

4)Pharmaceutical Manufacturing: API (Active Pharmaceutical Ingredient) separation and purification.

5)Wastewater Treatment: Sludge dewatering and thickening.

-

Durability & Longevity: Screens manufactured from high-quality materials like stainless steel (304, 316L, 904L), Duplex, or other special alloys offer excellent resistance to corrosion, abrasion, and high temperatures.

Types of Centrifuge Basket Screens – Finding Your Perfect Fit

There are two main types of centrifuge basket screens:

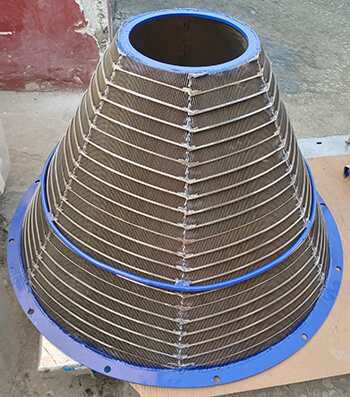

1.Wedge Wire Screens (Slotted Screens): Constructed from V-shaped profile wires welded to support rods, creating continuous slots with high open area and excellent anti-clogging properties. Ideal for fine particle separation and dewatering.

2.Perforated Plate Screens: Feature round, square, or custom-shaped holes drilled or punched into a metal plate. Often used for coarser separation or when specific hole shapes are required.

The choice between these, along with material selection, slot/hole size, and overall design, depends heavily on the specific application, particle size, chemical environment, and desired outcome.

Why Choosing the Right Centrifuge Basket Screen Manufacturer Matters

The performance of your centrifuge is directly tied to the precision and quality of its screen basket. Partnering with an experienced Centrifuge Basket Screen manufacturer like YUBO ensures you receive:

- Precision Engineering: Screens manufactured to exact tolerances for optimal fit and performance.

-

High-Quality Materials: Ensuring durability, corrosion resistance, and longevity.

-

Customization Capabilities: Tailoring screen design, slot/hole size, and material to your unique process requirements.

-

Expert Support & Consultation: Guidance in selecting the ideal screen for your application.

-

Reliable Supply & Global Reach: As foreign trade specialists, we understand the importance of timely delivery and international logistics.

Ready to Optimize Your Separation Process?

The Centrifuge Basket Screen is more than just a component; it's a cornerstone of efficient industrial separation. Understanding its purpose and choosing the right screen can unlock significant improvements in your product quality, operational efficiency, and bottom line.

If you're looking for high-performance, durable, and precisely engineered Centrifuge Basket Screens tailored to your specific needs, YUBO is here to help. Our expertise in screen technology and international trade makes us the ideal partner for businesses worldwide.

Contact us today for a consultation or to request a quote!

Visit our website: https://www.ubowedgewire.com

Email us: sales@ubowedgewire.com

Call us: 86-17363013056

Let YUBO be your trusted source for all your Centrifuge Basket Screen requirements!

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient