sieve bend screen design

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

This article explains in detail the key elements of sieve bend screen design and related contents.

In industries from mineral processing to wastewater treatment, the efficiency of solid-liquid separation is paramount. Inefficient separation leads to downstream equipment damage, lower product quality, and increased operational costs. While many technologies exist, the sieve bend screen stands out for its elegant simplicity, high efficiency, and low maintenance requirements.

However, not all sieve bend screens are created equal. The effectiveness of this powerful tool lies entirely in its design. A well-engineered sieve bend screen can dramatically improve your process, while a poorly designed one can become a bottleneck.

This guide explores the critical elements of sieve bend screen design to help you understand what to look for when sourcing a solution for your operations.

What is a Sieve Bend Screen?

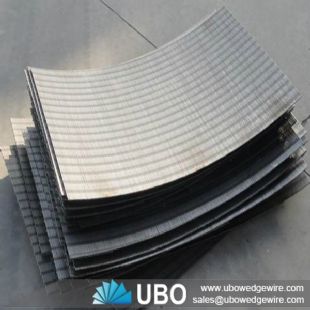

A sieve bend screen, also known as a static screen, parabolic screen, or DSM screen, is a non-mechanical screening device. It consists of a curved screen surface made from V-shaped profile wires, commonly known as wedge wire. The screen is mounted in a housing, and a slurry is fed tangentially onto the upper surface.

The Science Behind the Sieve Bend: How It Works

The genius of the sieve bend screen lies in its use of physics to achieve separation without any moving parts.

- Tangential Feed: The slurry (a mix of solids and liquids) is introduced at a specific velocity onto the top of the curved screen.

- Cross-Flow Separation: As the slurry flows down the screen, the sharp leading edge of each wedge wire "slices" away a thin layer of water and fine particles, which pass through the slots.

- Coandă Effect: The curved surface helps the liquid adhere to the screen, maximizing the opportunity for it to pass through the slots.

- Solid Discharge: The larger solid particles are retained on the screen's surface and, due to gravity and momentum, continue to slide down and are discharged from the bottom edge.

This continuous, self-cleaning process allows for high-capacity screening and dewatering in a compact, energy-efficient package.

Critical Elements of Sieve Bend Screen Design

The performance of a sieve bend is dictated by several interconnected design parameters. A reliable manufacturer will work with you to customize these elements for your specific application.

1. The Heart of the Screen: Wedge Wire Profile and Slot Size

The screen surface itself is the most critical component.

- Wedge Wire: The V-shaped profile wires (or wedge wires) provide a large open area while maintaining excellent structural strength. This design minimizes clogging, as particles only have two points of contact.

- Slot Size: The gap between the profile wires determines the separation cut point. Slot sizes can range from very fine (e.g., 0.25 mm for fine particle recovery) to coarse (e.g., 3.0 mm for scalping). The right slot size is crucial for achieving your desired level of separation without sacrificing flow capacity.

-

Material: The choice of material impacts longevity and compliance. Stainless Steel 304, 316L, and Duplex steels are common choices due to their excellent corrosion and abrasion resistance, making them ideal for harsh industrial environments.

2. The Power of the Curve: Arc Angle and Radius

The curvature of the screen is not arbitrary. The arc angle (commonly 45°, 60°, or 120°) and the radius of the curve are engineered to control the slurry's residence time and velocity.

- Shallower Arcs (e.g., 45°): Often used for higher capacity scalping.

-

Deeper Arcs (e.g., 60°, 120°): Provide longer residence time, making them ideal for finer separations and dewatering applications.

3. Optimizing Flow: Feed Box and Inlet Design

How the slurry is introduced to the screen is just as important as the screen itself. An optimized feed box is designed to:

- Convert the pressure of the incoming feed into head.

- Distribute the slurry evenly and tangentially across the entire width of the screen.

Poor feed distribution leads to uneven screen wear, reduced efficiency, and potential blinding.

4. Built to Last: Housing and Structural Support

The housing protects the screen and contains the process streams. A robust housing design ensures:

- Structural Integrity: Withstands the pressure and weight of the slurry flow.

- Proper Sealing: Prevents leaks and bypass.

- Ease of Access: Allows for simple inspection and screen replacement.

- Reversible Screen Feature: The most advanced designs allow the screen panel to be physically reversed. Since most wear occurs at the top (feed) section, reversing the screen doubles its operational life, significantly reducing maintenance costs and downtime.

Common Applications Across Industries

The versatility and reliability of well-designed sieve bend screens make them essential in a wide range of global industries:

- Mineral Processing: Dewatering minerals, desliming, and media recovery.

- Pulp and Paper: Fiber recovery and wastewater clarification.

- Food and Beverage: Starch processing, fruit and vegetable juice clarification, and solids recovery from wastewater.

- Wastewater Treatment: Primary screening of municipal and industrial wastewater.

- Sugar Processing: Bagasse dewatering and juice screening.

- Chemical Processing: Plastic pellet dewatering and solids classification.

Choosing the Right Sieve Bend Screen Partner

When investing in equipment for your plant, you are not just buying a product; you are investing in a solution. Your supplier should be a partner who understands the nuances of solid-liquid separation.

Look for a partner with:

- Customization Capability: A one-size-fits-all approach doesn't work. Your partner must be able to engineer a sieve bend screen tailored to your specific flow rates, particle sizes, and process goals.

- Material Expertise: They should offer and advise on the correct materials (e.g., SS316L for corrosive environments) and provide material certifications.

- Proven Technical Expertise: Ask for case studies, application data, and access to engineers who can help you optimize your design.

-

Global Experience: A supplier experienced in foreign trade understands international standards, logistics, and the importance of clear communication and reliable after-sales support.

Conclusion: Design is the Difference

The sieve bend screen is a testament to brilliant, simple engineering. Its ability to deliver high-performance separation with no moving parts makes it a cost-effective and reliable choice for any operation.

However, its performance is entirely dependent on its design. By focusing on the critical elements—wedge wire selection, screen curvature, feed distribution, and robust housing—you can ensure you are investing in a solution that will enhance your process efficiency, minimize maintenance, and deliver a rapid return on investment.

Ready to optimize your solid-liquid separation process?

The technical engineers team of sieve bend screen manufacturer Hebei YUBO Filtration Equipment Co.,Ltd. has extensive experience designing and manufacturing high-performance sieve bend screens for clients worldwide. We are ready to analyze your application and recommend a custom-designed solution that meets your exact specifications.

Contact our technical sales team today to discuss your project and receive a no-obligation quote.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient