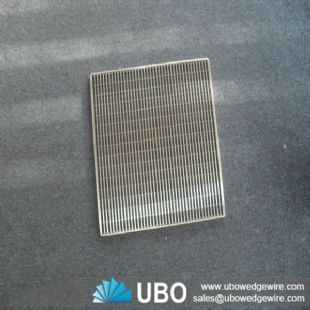

Vee Wire Screen Non-Clogging Filter

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

In industrial processes, nothing is more frustrating and costly than filter clogging. It cripples efficiency, skyrockets maintenance costs, and forces unnecessary production downtime.

For engineers seeking the ultimate filtration solution, one that guarantees superior separation and minimal clogs, the vee-wire screen (also known as wedge wire) consistently proves itself as the undisputed #1 choice.

The Problem Solved: Anatomy of a Clog-Stopper

The genius of the vee-wire screen lies in its simple, yet highly effective, design:

▪ V-Shaped Wires: Unlike traditional woven mesh that uses square openings, vee wire screens use V-shaped wires resistance-welded to support rods.

▪ The Tapered Slot: This creates a continuous slot opening that widens inward.

How It Stops Clogs: This inward taper ensures that any particle that passes the narrowest point on the surface will continue to flow through without impedance. There are no sharp corners or bridging points for materials to lodge and accumulate. This non-clogging feature is the core reason for its high efficiency.

Superior Flow: The design maximizes the screen’s open area, allowing for high flow rates with significantly less pressure drop compared to conventional screens.

Built to Last: Typically constructed from corrosion-resistant stainless steel (304 or 316L), the welded, one-piece structure offers exceptional strength, resistance to abrasion, and a long service life in harsh chemical environments.

Real-World Performance & Key Applications

The vee-wire screen's reliability makes it indispensable across critical high-stakes industries:

| Industry | Application Highlight | Key Benefit |

| Water Treatment | Intake screening, wastewater processing, sediment removal. | Maximum Uptime: Protects sensitive pumps and ensures compliance. |

| Oil & Gas | Downhole well screens, sand control, and filtering drilling fluids. | High Pressure Resistance: Maintains integrity under extreme subterranean conditions. |

| Mining & Minerals | Dewatering, mineral sizing, solid-slurry separation. | Abrasion Resistance: Withstands continuous flow of highly abrasive materials. |

| Food & Beverage | Breweries (lauter tun screens), dairy, and juice filtration. | Sanitation & Purity: Non-contaminating stainless steel and easy backwashing. |

When you choose a vee-wire screen, you're not just buying a filter; you're investing in operational stability. The technology minimizes maintenance, reduces energy consumption, and virtually eliminates the high costs associated with clogging and downtime.

If your process demands consistent, high-volume flow and superior separation, the vee-wire screen is the proven solution you need to stop the clogs and boost your bottom line.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient