how to select the right sieve bend screen

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

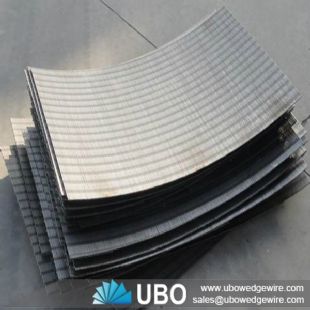

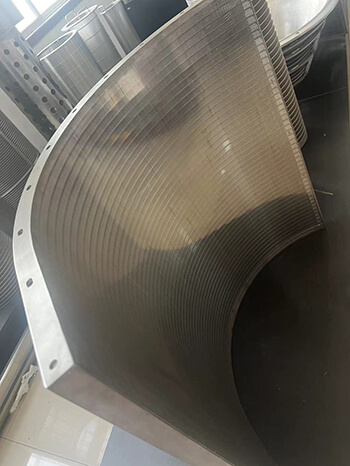

As a critical component in solid-liquid separation, the sieve bend screen—also known as a static screen or DSM screen—is a powerhouse of efficiency. Its simple, non-moving design offers exceptional dewatering and classification with minimal maintenance. However, selecting the wrong screen can lead to poor performance, frequent clogging, and costly downtime.

Choosing the right sieve bend screen isn't just about buying a product; it's about engineering a solution. As a specialized sieve bend screen manufacturer, Hebei YUBO Filtration Equipment Co.,Ltd.(hereinafter referred to as “YUBO”) know that success lies in the details. This comprehensive buyer's guide will walk you through the three most critical factors to consider: slot size, material, and arc angle, ensuring you invest in a screen that is perfectly optimized for your application.

1. The Critical Role of Slot Size (Opening)

The slot size is arguably the most important factor in a sieve bend screen's performance. It directly determines the separation cut point—the size of the particle that will be separated from the liquid.

-

Too large, and you'll lose valuable solids in the effluent.

-

Too small, and the screen may blind or clog, reducing capacity and efficiency.

How to Determine the Ideal Slot Size:

A general rule of thumb is to select a slot size that is approximately half the size of the particle you wish to separate. For example, if you need to separate 1mm mineral particles, a slot opening of 0.5mm (500 microns) is an excellent starting point. This allows the unique Coanda effect of the screen to effectively shear water away while retaining the solids.

Common Applications and Corresponding Slot Sizes:

- Mineral Processing (e.g., Coal Fines): 0.25mm - 1.5mm

-

Pulp & Paper (Fiber Recovery): 0.5mm - 2.0mm

-

Food Processing (Starch, Vegetable Washing): 0.15mm - 1.0mm

- Wastewater Treatment (Primary Screening): 1.0mm - 3.0mm

As a custom sieve bend screen manufacturer, YUBO can produce sieve bend screens with precise slot openings tailored to your specific particle size distribution for unparalleled separation accuracy.

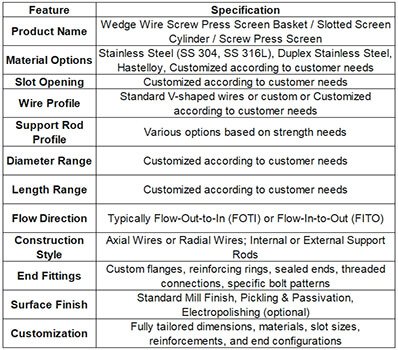

2. Choosing the Right Material for Durability and Lifespan

Your sieve bend screen will be constantly exposed to your process flow, which may be abrasive, corrosive, or operate at high temperatures. Selecting the correct material is essential for ensuring a long service life and preventing premature failure.

Here is a quick comparison of common materials:

The choice of material directly impacts the total cost of ownership. While a standard SS304 screen may have a lower initial cost, investing in SS316L or a specialty alloy for a corrosive environment will save you money on replacements and downtime in the long run.

3. Understanding the Arc Angle and Its Impact on Performance

The curved profile of the sieve bend is what creates the hydraulic force needed for separation. The arc angle of this curve plays a significant role in balancing dewatering efficiency and flow capacity.

-

Shorter Arc Angles (e.g., 45°, 60°): These angles provide a sharper, more aggressive shearing action. They are ideal for applications requiring maximum dewatering and a drier solids discharge. They are common in mineral and sand dewatering.

-

Longer Arc Angles (e.g., 120°, 270°): A longer arc provides more screen area and a longer residence time for the slurry. This is beneficial for applications that require high flow capacity and the classification of fine particles. These are often used in starch processing and thickener protection.

The optimal arc angle depends on your primary goal. Do you need the driest possible solids, or do you need to process a very high volume of liquid? YUBO's engineers can help you model the performance based on your flow rate and separation goals to specify the perfect arc.

Partner with YUBO's Experts for Your Custom Sieve Bend Solution

Selecting the right sieve bend screen is a technical decision that impacts your entire process. By carefully considering the slot size, material, and arc angle, you can ensure optimal performance from day one.

Don't leave your productivity to chance. YUBO's team of engineers specializes in designing and manufacturing custom sieve bend screens that are built to your exact specifications. We analyze your process parameters—including flow rate, particle size, and chemical composition—to recommend and build the perfect solution for you.

Ready to maximize your separation efficiency?

[Contact Us] for a no-obligation technical consultation and a personalized quote for your custom sieve bend screen. Let YUBO help you get it right the first time.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient