what is the wedge wire screen

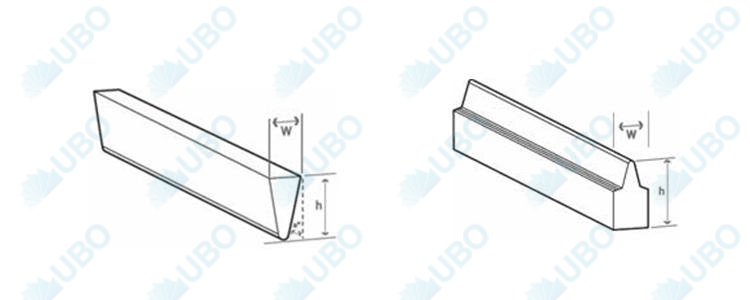

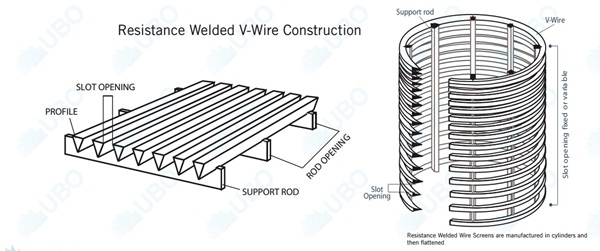

It is a sieve made from looped wires formed into a deep wedge-shaped section. Individual wedge wires are built into " Panels " by threading cross rods of suitable diameter through the loops. The whole is then clamped and made secure usually by riveting or putting ring nuts over the cross rod ends or by welding.

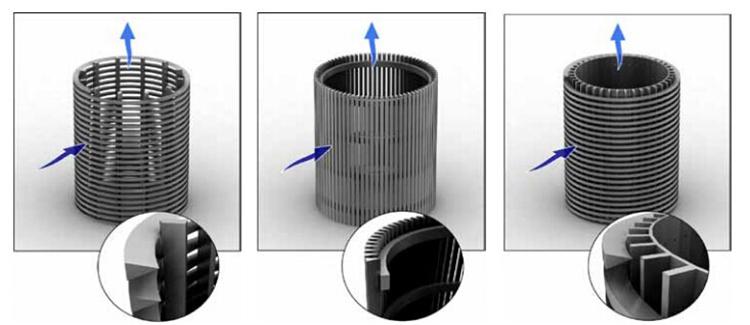

The wedge wire screens can be supplied in various shapes and forms as per the requirements such as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments. For curved, cylindrical and conical screens in most cases the cross rods lie along the circumference and profile wires run parallel to the axis. Occasionally this arrangement is reversed.

Advantages of wedge wire screen

Wedge Wire Screens provide a unique combination of the most important features required for maximum screening efficiency.

A. Free Clearance

The wedge-shaped sections of the wire from aperatures that become progressively wider in a downward direction, thus ensuring rapid flow of material through them. Clogged and blinded aperatures are reduced to an absolute minium.

B. Lateral Strength

In our opinion no form of screening surface witl i apertures as fine as those of wedge wire screens, can compare with the mechanical strength and working efficiency of wedge wire.

C. Percentage Open Area

For a given aperature size, wedge wire screens have a much larger percentage of open area than conventinal sieves.

D. Wearing Life

Owing to a greater wearing area being provided by hat top surfaces, wedge wire screens retain their aperature for a longer duration than round wire screens.

Some other advantages of Looped type of wedge wire screens over other type of screens and also other type of wedge wires are

Self Supporting High Abrasition resistance Low pressure drop High resistance to Vibration

Looped Wedge Wire Screen construction is particularly recommended when high Vibration resistance and fine accurate aperture are needed.