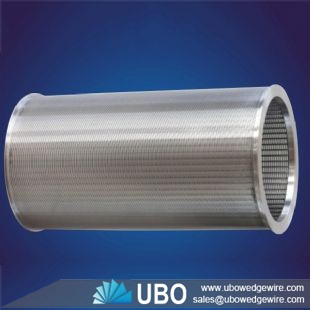

Rotary Sieve Wedge Wire Drum Screen

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | wedge wire screen |

| Application: | the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatme |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Rotary Sieve Wedge Wire Drum Screen

Rotating screen is a mechanical self-cleaning device that was developed to meet the growing need and demand for an efficient and economical method of removing suspended solids from mixed liquid streams. The continuous and self-cleaning effect of the rotating screens makes it possible to use higher flow capacities than those of any other type of screen thus resulting in substantial savings with respect to both investment and maintenance.

Usages for Rotary Sieve Wedge Wire Drum Screen:

The wedge wire screen or strainer is a kind of filtered water tubing with the perforation. It can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, also used in the petroleum industry as fittings for the petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and the organic solution recycling filters.

Advantage for Rotary Sieve Wedge Wire Drum Screen:

The Ladder-like wire welded wedge wire screens have a strong structure and high open area, as well as accurate slot dimension.

The screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Features for Rotary Sieve Wedge Wire Drum Screen:

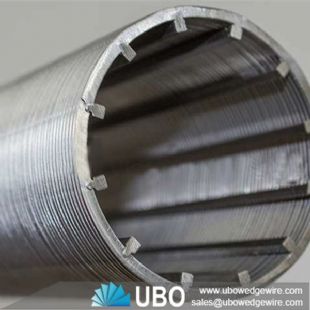

Original differential rotation screen design:

The external rotating cylindrical screen means that a fresh filtration surface is constantly presented in the thickening zone, realizing high filtration performance and allowing a high degree of thickening over a short distance. Further, the external rotating cylindrical screen means a uniform and tightly consolidated cake layer is formed within the press dewatering zone and that the cake has a lower water content comparing to a fixed external cylinder type screw press.

High separation wedge wire screen:

Maintaining a high aperture ratio and high degree of strength, the wedge wire screen can separate sludge quickly and maintain a fast filtration speed. In addition, the wedge wire screen does not clog easily and can be efficiently washed and cleaned using small quantities of water.

Water content control system:

The screw press equipped with a constant feed pressure control system which maintains the solid matter load at a constant figure. This allows a consistent recovery rate of suspended solids in the effluent and a consistent water content in the dewatered cake.

Specifications of Rotary Sieve Wedge Wire Drum Screen:

|

Size

(inch)

|

O.D

(mm)

|

Slot

(inch)

|

Collapse Strength

(Psi)

|

Tensile Weight

(Ton)

|

Wrap(thick*deep)

(mm)

|

Rods

(mm)

|

|

4

|

117

|

0.04

|

395

|

6

|

2.2*3.0

|

3.8mm/22

|

|

4

|

114.3

|

0.04

|

395

|

6

|

2.3*3.0

|

3.8mm/22

|

|

6

|

168.3

|

0.04

|

252

|

8

|

2.3*3.5

|

3.8mm/32

|

|

8

|

219.1

|

0.01

|

399

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.02

|

370

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.04

|

323

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

10

|

273.1

|

0.01

|

206

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.02

|

191

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.04

|

167

|

11

|

3.0*5.0

|

3.8mm/50

|

Packaging and Transportation of Rotary Sieve Wedge Wire Drum Screen: