how does a false bottom work brewing

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

A false bottom is a device used in brewing, particularly in the mashing and lautering processes of beer production. It is designed to separate the liquid wort (the sugary liquid extracted from the malted grains) from the solid spent grains during these processes. The false bottom is typically placed at the bottom of the mash tun or lauter tun, which are vessels used in brewing.

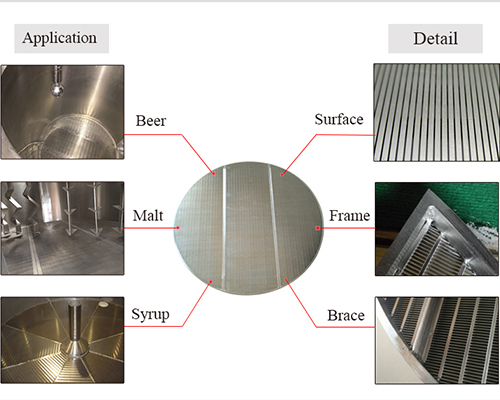

Stainless Steel Mash Tun False Bottom Factory

YUBO Filtration is capable of custom designing different types and sizes of stainless steel false bottoms for mash tuns used in brewing. Our false bottoms are crafted from food-grade stainless steel material, ensuring high quality at a competitive price. We offer factory-direct pricing and specialize in tailor-made designs to meet your specific needs.

Here's how a false bottom works in the brewing process:

1. Mashing: During mashing, crushed malted grains are mixed with hot water in the mash tun. This mixture undergoes temperature-controlled rest periods to allow enzymatic reactions to convert the starches in the grains into fermentable sugars. The result is a mixture of liquid wort and spent grain husks.

2. Lautering: Once the mashing process is complete, the liquid wort needs to be separated from the solid spent grain husks. This separation process is called lautering. A false bottom is used to achieve this separation.

3. False Bottom: The false bottom is a perforated or slotted plate(wedge wire screen) that is placed at the bottom of the mash tun. It forms a barrier between the solid grain husks and the liquid wort. The slots or perforations in the false bottom allow the liquid wort to flow through while preventing larger pieces of grain from passing through.

4. Flow of Wort: As the liquid wort is drained from the mash tun, it flows through the false bottom and collects underneath it. The small gaps between the grains on the false bottom allow the wort to pass through while filtering out the spent grain husks.

5. Sparging: After the initial drainage of the wort, a process called sparging is often performed to rinse additional sugars from the grains. More hot water is added to the mash tun and allowed to flow through the grain bed. The false bottom ensures that the added water can flow through the grains and collect as wort while keeping the grains in place.

6. Efficiency and Clarity: The false bottom aids in achieving efficient extraction of sugars from the grains and also helps clarify the wort by preventing solid particles from entering the collected liquid. This clear wort is then transferred to the next stages of the brewing process, such as boiling and fermentation.

In essence, a false bottom is a filtration device used in brewing to separate liquid wort from spent grain husks during mashing and lautering. It plays a crucial role in maintaining the quality of the wort and ensuring that the brewing process proceeds smoothly.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient