correct temporary strainer installation direction

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

Introduction: Why Temporary Strainer Installation Direction is Crucial

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.(hereinafter referred to as “YUBO”), your trusted partner in high-quality temporary strainers for global industries! Temporary strainers, also known as commissioning strainers or startup strainers, play a vital role in protecting valuable downstream equipment like pumps, meters, and valves from debris during pipeline commissioning, startup, or after maintenance. However, their effectiveness hinges entirely on correct installation, especially the flow direction.

Installing a temporary strainer in the wrong direction can lead to inefficiency, damage to the strainer itself, or even failure to protect your equipment. This guide will walk you through the correct installation direction for common types of temporary strainers, ensuring you get the maximum benefit and protection.

Understanding the Basics: How Temporary Strainers Work

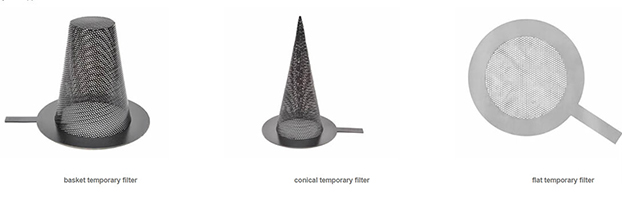

Before diving into installation direction, let's briefly recap how temporary strainers function. They are designed to be inserted between flanges in a pipeline to catch and remove unwanted solids – weld slag, rust, construction debris – from the process fluid. The design of the strainer (conical, basket, or plate) dictates how it interacts with the flow.

The Golden Rule: Flow Into the "Mouth," Out Through the Mesh

While specific designs vary, the fundamental principle for most temporary strainers is that the process fluid should flow into the open end (or wider part) of the strainer and exit through the perforated or mesh surface. This allows debris to be collected efficiently within or on the surface of the strainer.

Installation Direction for Different Types of Temporary Strainers

1.Conical Strainers (Cone Strainers / Witch Hat Strainers):

-

Description: These are shaped like a cone, with the point extending in one direction.

-

Correct Installation Direction: The pointed end of the cone MUST point downstream (in the direction of the flow). The open, wider base of the cone faces upstream, "catching" the flow.

-

Why: Debris is collected on the inside surface of the cone. If installed backward, flow pressure could collapse the cone or force debris around it.

-

Visual Cue: Imagine an arrow – the point of the cone is the arrowhead showing flow direction.

2.Basket Strainers (Truncated Cone Strainers):

-

Description: Similar to conical strainers but with a flat end instead of a point, resembling a truncated cone or a simple basket.

-

Correct Installation Direction: The open, wider end of the basket MUST face upstream (against the flow). The flat, perforated end points downstream.

-

Why: Debris collects inside the basket. Incorrect installation would be inefficient and could damage the strainer.

3.Plate Strainers (Flat Strainers / Paddle Blinds with Mesh):

-

Description: These are flat, perforated plates, often with a solid handle (paddle).

-

Correct Installation Direction: Plate strainers are installed perpendicular to the flow, with the perforated area fully covering the pipe bore. The flow passes directly through the mesh. The orientation of the handle is typically for ease of access and visibility, not flow dynamics.

-

Why: Debris collects on the upstream face of the plate.

General Installation Guidelines for Temporary Strainers:

-

Verify Flow Direction: Always double-check the indicated flow direction on the pipeline itself before installation.

-

Use Correct Gaskets: Ensure new, correctly sized gaskets are used on both sides of the temporary strainer to prevent leaks. The strainer itself does not typically provide a seal.

-

Flange Alignment: Ensure flanges are properly aligned before inserting the strainer.

-

Sufficient Space: Temporary strainers often require more space between flanges than a standard gasket. Ensure there's enough "give" in the pipeline to insert them.

-

Handle Orientation (for Cone/Basket types with handles): Position the handle (if present) for easy identification and removal.

-

Pressure Drop Monitoring: After installation and startup, monitor pressure drop across the strainer. A significant increase indicates it's clogging and needs cleaning or removal.

-

Removal Plan: Remember, these are temporary. Have a plan for their removal after the commissioning or cleaning phase is complete.

Consequences of Incorrect Temporary Strainer Installation:

-

Reduced Efficiency: The strainer won't capture debris effectively.

-

Strainer Damage: Incorrect flow can bend, crush, or tear the strainer mesh.

-

Equipment Damage: Failure to capture debris means your downstream equipment is unprotected.

-

Increased Pressure Drop: Incorrect orientation can cause an unexpectedly high pressure drop.

-

Safety Hazards: A damaged or improperly seated strainer could lead to leaks or failure.

Why Choose YUBO for Your Temporary Strainers?

At YUBO, we specialize in manufacturing high-quality temporary strainers designed for reliability and performance. We understand the critical nature of correct installation and offer:

-

Expert Guidance: Our team can advise on the best strainer type and installation practices for your specific application.

-

Premium Materials: We use robust materials to ensure durability even in demanding conditions.

-

Custom Solutions: Need a specific size or mesh? We can manufacture custom temporary strainers to your exact requirements.

-

Global Shipping: As experienced foreign trade operators, we efficiently ship our products worldwide.

Get Your Temporary Strainer Quote Today!

Don't compromise on pipeline protection. Ensure you're using the right temporary strainers and installing them correctly.

Contact us today for a no-obligation quote or to discuss your temporary strainer needs. Our experts are ready to help you select the perfect solution for your project.

-

Email: sales@ubowedgewire.com

- Phone: 86-173 6301 3056

- Visit our Product Page: https://www.oemubo.com/wedge-wire-tube/temporary-strainer.html

- Request a Quote Online: https://www.ubowedgewire.com/About/contact-us-22-1.htm

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient