Talking about the factors related to the flatness of the punching mesh

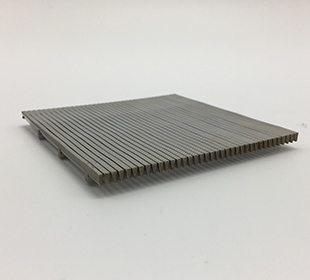

The main specifications of punching mesh are rectangular holes, square holes, diamond holes, round holes, oblong holes, hexagonal holes, cross holes, triangular holes, long waist holes, plum blossom holes, fish scale holes, pattern holes, figure meshes, herringbone Holes, pentagram star holes, irregular holes, drum holes, special-shaped holes, louver holes, etc.

How to ensure the flatness of the punching mesh depends on what factors?

1. It is related to aperture and pitch. The smaller the distance between the holes and the denser the flatness, the worse the flatness. When the CNC punching is stressed, a punching process of the punch pin and the stainless steel plate is equivalent to annealing the stainless steel plate, so the plate becomes hard and not smooth.

2. Related to the material. The degree of deformation of different materials after stamping is not the same. The degree of deformation of stainless steel is large and it is difficult to level. This is because of the rigidity of stainless steel and its toughness, so the later leveling is difficult to reach the same level as before no punching. Flatness.

3. What affects the flatness is the margin of the board. The larger the margin, the worse the flatness, especially the larger the opening rate, the larger the aperture, and the larger the margin on the four sides, the more difficult it is to level. Even if it is leveled, it will be a punching mesh because of transportation, loading and unloading Deformed again.

Questions that need to be paid attention to when punching machine is making punching mesh

1. In the punching process, it is necessary to ensure the verticality of the punching. The verticality is very important. Some deviations occur because this will cause the lateral force of the punching mesh (round hole mesh) to increase when punching. The quality is not good and it is easy to break.

2. Insufficient protection of punching mesh (round hole mesh) punches. In the design, the punching mesh punches are reinforced or protected by protective sleeves.

3. If the thickness of the stainless steel plate is different, different punching speeds should be used for the punching mesh to ensure the service life of the punching mesh.

We are a large-scale industrial enterprise integrating production and sales. It is famous in the country for its production of wedge wire screen, wedge wire filter nozzle, Wedge Wire pipe, sintered filter, and other products. It is highly praised by users and experts.