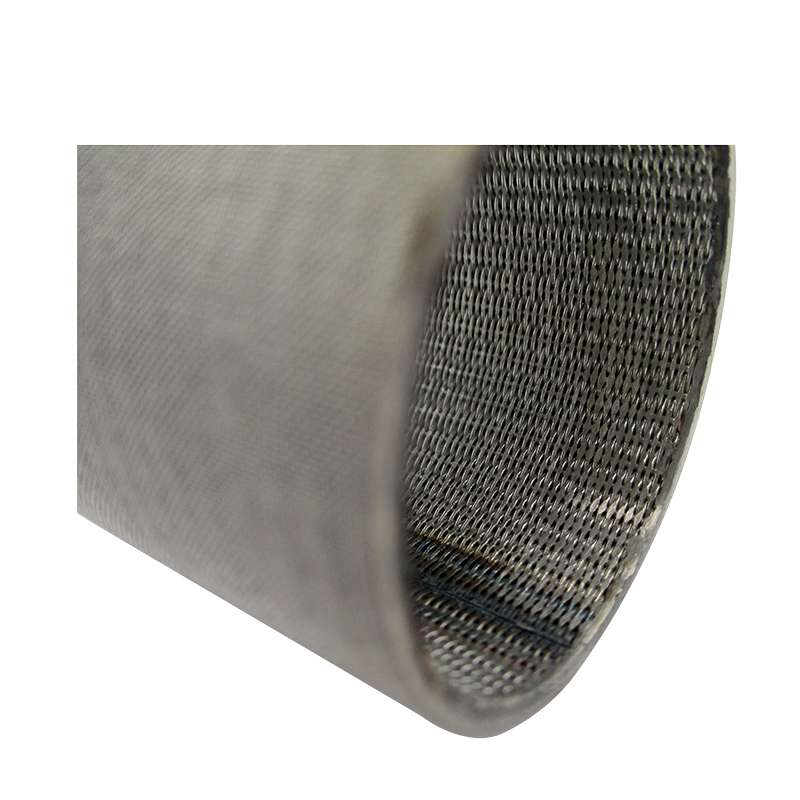

Clean methods of the sintered filter element

Welcome to Hebei YUBO Filtration Equipment Co.,Ltd.

The sintered filter element can be regenerated by physical and chemical methods according to the pollution situation and the chemical properties of the contaminant combined with the physicochemical properties of the stainless steel.

Physical methods: clean liquid recoil, clean gas backflushing and ultrasonic cleaning.

Chemical methods: dilute acid, dilute alkali, oxidizing agent, surfactant, enzyme and other cleaning agents.

The above various methods can also be used interchangeably.

According to several common applications, the specific cleaning methods are as follows:

Decarbonization filtration: Decarbonization filtration in the pharmaceutical and chemical industries, using back flushing, back washing methods combined with ultrasonic cleaning.

Water-making industry: Because the surface of the filter core is mostly water-insoluble salts and oxides, it is generally immersed in 5% nitric acid, and the cleaning effect can be achieved without ultrasonic cleaning.

Raw liquid filtration: To combine the chemical properties of the contaminants, the following methods are used for cleaning:

Alkaline washing: soaking with 3-5% sodium hydroxide analytical pure solution for 30-60 minutes, temperature about 40 degrees, the best in ultrasonic cleaning machine. After soaking, filter the deionized water or the inside and outside of the injection water to neutral, and measure the conductivity. Dry with pure air ≥ 0.4MPa pressure.

Pickling: Soak in a 5% nitric acid solution for more than 8 hours at a temperature of about 40 degrees. Best in ultrasonic cleaners. After soaking, rinse with deionized water or water for injection to neutral, side conductivity. Dry with pure air ≥ 0.4MPa pressure.

Surfactant cleaning: Organic substances can be cleaned by surfactants. For example, the cell debris contamination system combined with enzyme cleaning is more effective (food and beverage can be washed with high concentration of citric acid).

The above methods can be used alone or in combination with each other. The effect is best when combined with an ultrasonic cleaner.

We are the sintered filter element designer and manufacturer in China, welcome contact us if you want to know more about the filter elements informations.

Who We Are?

YUBO Company is the professional supplier in China. It is always committed to study, design and produce wedge wire screen products for industry filter.Now its products include wedge wire screen panel, filter nozzle, cylinder,basket,pipe, Sieve Bend Screen,Profile Screen Laterals,etc.

What Is wedge wire screen

Wedge Wire Screens is a sieve made from looped wires formed into a deep wedge-shaped section. The wedge wire screens can be supplied in various shapes and forms as FLAT PANELS, CURVED SIEVE BENDS, CONICAL BASKETS, CYLINDERS, TROUGHS DISKS either in one one piece or in segments.

our advantages

- Professtional, we have our Engineering designers

- We are the factory

- Quality is our cluture and soul

- Customized. We produce and design according to your need

- Low cost and high efficient