Wedge Wire Screen Product Technical Requirements

The reason why the wedge-shaped wire mesh blocks the net: The wedge-shaped wire mesh screen surface reciprocates linearly under the action of the vibration exciter, and the particles are thrown and dropped under the vibration of the screen surface, and the ejection and falling of the material have an impact on the screen surface. The particles smaller than the mesh are caused to be sieved, so that the material is classified according to the size of the particles. There are many factors affecting the permeability of the material, but there are two main categories in summary. One is the various characteristics of the material itself, and the other is the wedge-shaped mesh structure.

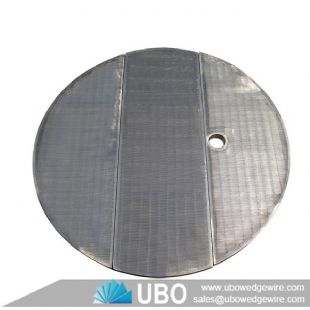

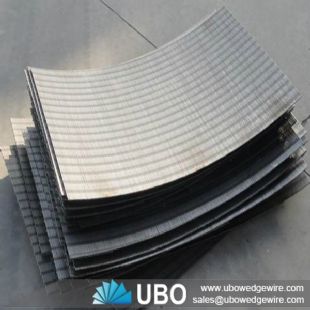

The wedge wire screen tiems is a metal mesh structure element for screening filtration. Widely used in screening, filtration, dehydration, deliming and other operations in many industries. It has high strength, rigidity and load carrying capacity and can be made into rigid screening filters of various shapes. The wedge wire mesh is machined by an advanced fusion welding process. The slotted screen surface has high screening efficiency, strong shock resistance, low maintenance requirements, and long service life.

Wedge wire screen is mainly used in the classification of dewatering, de-intermediation and de-sludge of fine-grained materials widely used in coal, chemical, environmental protection and other industries. It is generally used in conjunction with heavy medium cyclones. The most common stainless steel wedge wire screens are installed on the high-frequency linear vibrating screen for coal carbon screening and classification. The special structure can effectively cut and classify the materials to achieve the best use effect for users. The high-quality stainless steel mesh screen plate produced by our factory is made of high-quality stainless steel non-magnetic raw material. It is formed by high-precision wire-pressing machine once, and the sieve wire is trapezoidal. It has strong bearing capacity and high wear-resistance coefficient. The mine screen is a welded screen, which is a metal mesh structural element used for screening and filtration. It is a kind of strip-shaped stainless steel welded sieve plate with various specifications, but it is used to classify materials. , cutting, screening effects. It has the characteristics of high screening rate, wear resistance, corrosion resistance, anti-skid, anti-vibration, strong elasticity, strong toughness and no close together. It is the highest-end screen product in the coal industry. The various types of mine screens produced by our factory are strictly made of high-quality stainless steel materials produced by large steel mills. The mesh screen of the products is even, the welding quality is stable, the opening ratio is high, the service life is long, and it is very high. The strength, rigidity and load carrying capacity can guarantee the service life of the product and meet the demanding requirements of various coal types. The washing coal mine screen can be divided into: polyurethane screen, manganese steel screen, stainless steel screen. The most common of these is the stainless steel ore screen.